How does pressure transmitter for HVAC work: Simple Guide

What does a pressure transmitter do?

A Pressure transmitter for HVAC is a pressure measuring device that has a use for measuring force. It is useful for the measurement of the pressure of a liquid or a gas sample. The pressure transducer is another name for the pressure transmitter. The basic purpose of this device is to measure the force exerted by the fluid.

The pressure transmitter consists of the surface area that is pressure sensitive. However, these surface areas of the transmitter consist of different materials like steel or silicon. The type of the material in the surface area depends upon the composition of the analyte.

What is the principle of the pressure transmitter?

The principle for the functioning of the Pressure transmitter for HVAC is simple. The sensor used in the transmitter can convert the mechanical signal into the electrical signal. The pressure sensor produces the proportional type of the electrical signal. However, it has a main body and a diaphragm.

What is the level transmitter working principle?

This type of transmitter works based on the principle of radar. However, the radar system for the level transmitter uses radio waves. The transmitter can send the radio signals to the surface of the liquid with the help of the radar system. After it, the transmitter can get the reflection of the signals.

When the level transmitter receives the reflection of the signals, then it analyses the level of the current fill in the tank. Usually, analysis of the current fill depends upon the time that the signal takes to reach back to the transmitter. Therefore, the level transmitter can measure the pressure of the liquid.

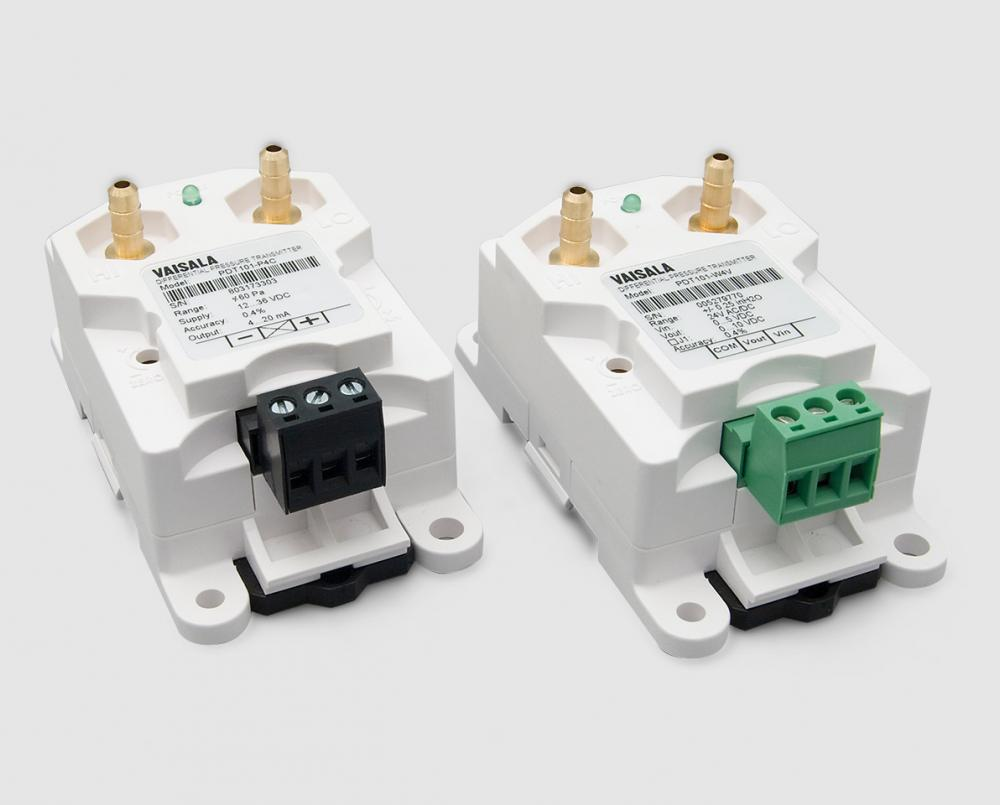

How does pressure differential transmitter work?

The pressure differential transmitter is a useful type of transmitter that is common in the measurement of pressure. As the name indicates, this transmitter is helpful in the measurement of the difference in the pressure between the two ports.

However, this Pressure transmitter for HVAC also produces an output signal. This output signal depends upon the range of the calibrated pressure. As I have mentioned that it measures the pressure difference between the ports that are high and low markings on them. In this way, we use this equipment for the sensing of the pressure difference.

What are the 4 types of pressure?

The pressure is the ratio between the applied force and surface area. It tells us about the amount of force that is applied to the unit surface area of the liquid. There are four types of pressure. These four types are absolute pressure, differential pressure, atmospheric pressure, and gauge pressure.

What is absolute pressure?

This is the type of pressure that depends on reference pressure. Therefore, this type of pressure is related to the reference pressure. We can measure it with the help of a Pressure transmitter for HVAC.

What is differential pressure?

The differential pressure is the type of pressure that is the difference between two pressures. Usually, we use the differential transmitter for the measurement of this type of pressure.

What is atmospheric pressure?

The atmospheric pressure is the type of pressure that is related to the atmosphere. This is the standard pressure that depends upon the weather. The standard atmospheric pressure value is 760mmHg. It is the pressure that is present at sea level.

What is gauge pressure?

The gauge pressure is a difference between two pressure values. It is the difference between the absolute pressure value and atmospheric pressure value.

What is the difference between the pressure gauge and pressure transmitter?

The pressure gauge is an instrument that is useful for the indication of the pressure value higher than the ambient value. However, for this purpose, the pressure gauge uses the elastic elements for the purpose sensing element. Therefore, the use of the pressure gauge is very useful in industrial processes and laboratory researches.

On the other hand, the Pressure transmitter for HVAC is a mechanical device that produces the output in the form of standard electrical signals. Therefore, this transmitter is useful to convert the mechanical value of pressure into the standard electrical value. There are commonly three parts of the pressure transmitter. These are sensing elements, measuring circuit, and process connection.

What are the common differences between the pressure gauge and pressure transmitter?

The common difference between the pressure gauge and pressure transmitter are following:

- For the calibration of the pressure transmitter, there is a need for the high standard instruments as compared to the pressure gauge.

- The pressure gauge is helpful in the verification of the relationship between the input and output. While the pressure transmitter helps to verify the connection between the input and the communication data.

- The measurement qualifications are the essential element in the calibration of the pressure gauge. While the calibration of the pressure transmitter requires the manufacturer with the new construction.

- The pressure gauge usually shows poor accuracy. The reason is that it has no output and we cannot operate it by hand.

- However, the Pressure transmitter for HVAConly needs to calibrate the zero point and the full scale.

What are the types of the transmitter?

There are four fundamental types of transmitters. However, these basic types have further subtypes that have different industrial uses and applications. These types are flow transmitter, temperature transmitter, pressure transmitter, and level transmitter.

What is a flow transmitter?

As the name indicates, this type of transmitter is of prime use for the measurement of the pressure on the surface of a liquid or gas sample. However, the signal moves to the sample and produces the output. There are different types of sensors that have the use in the manufacture of flow transmitters.

What are temperature transmitters?

The structure of the temperature transmitter depends on the working of the temperature sensor. The purpose of the sensor is to send the signals to the temperature transmitter. Ultimately, the transmitter converts this signal into the output signal and measures the temperature. However, the temperature transmitter has two important types.

Thermocouple type

This type of temperature transmitter has a thermocouple sensor for the detection of the temperature. However, this transmitter measures the temperature with the help of the electromotive force.

RTD type

This type of temperature transmitter consists of the RTD sensor. This RTD sensor can variate the resistance according to the temperature. This relationship becomes the source of calculating the temperature.

What is a pressure transmitter?

The Pressure transmitter for HVAC is the common type of transmitter for the measurement of the pressure in different processes. There are three further types of pressure transmitters. These are the absolute transmitter, gauge transmitter, and differential transmitter.

What are level transmitters?

The transmitters that are important in the measurement of the level of the liquids are called level transmitters. However, there are seven types of level transmitters. These seven types are point level transmitter, continuous level transmitter, ultrasonic level transmitter, conductive level transmitter, pneumatic level transmitter, capacitance level transmitter, and hydrostatic based level transmitter.

However, here are many industrial transmitters in the market for signal production in industrial applications.