- Introduction

- Technical data

- Electrical connection

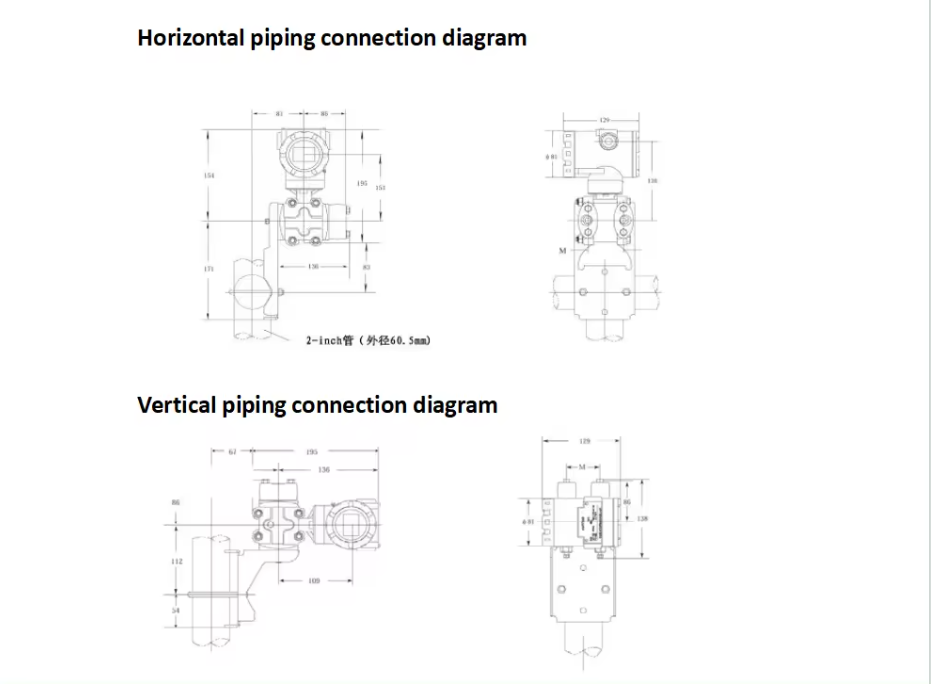

- Dimensions

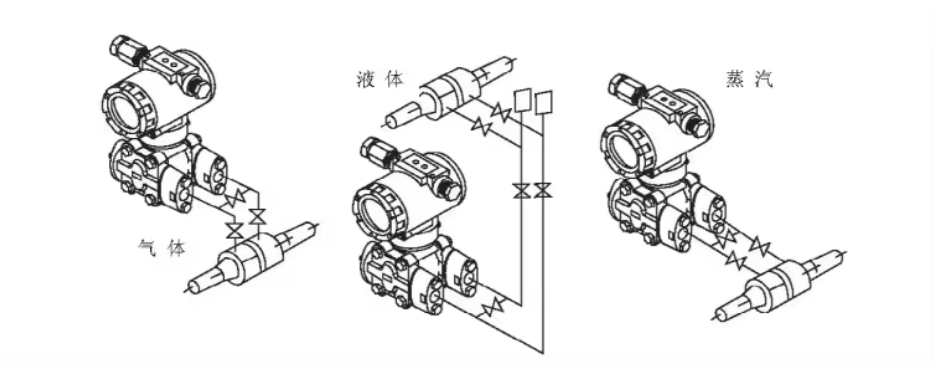

- Applications

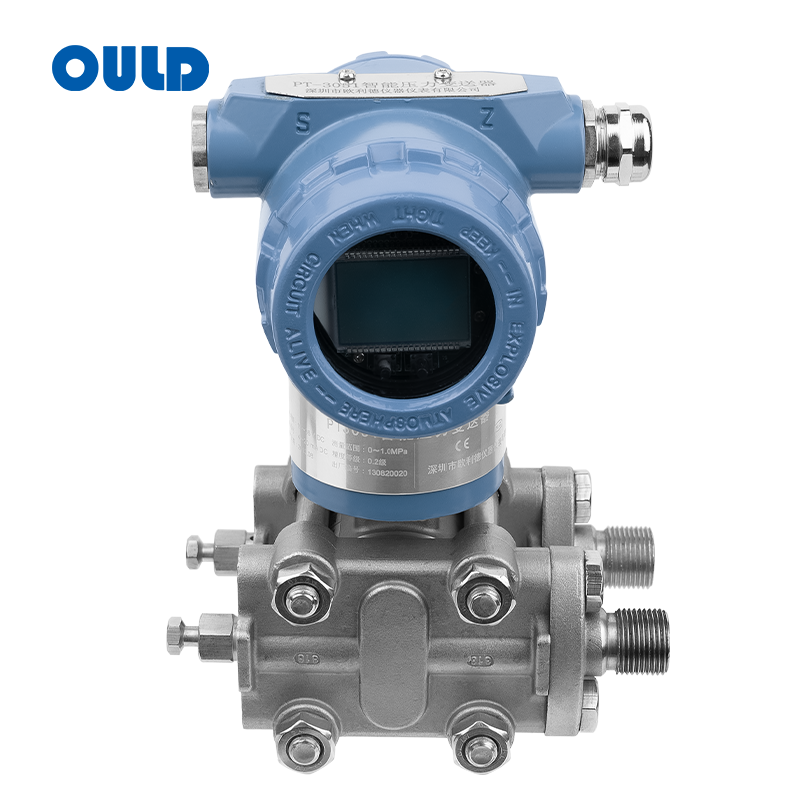

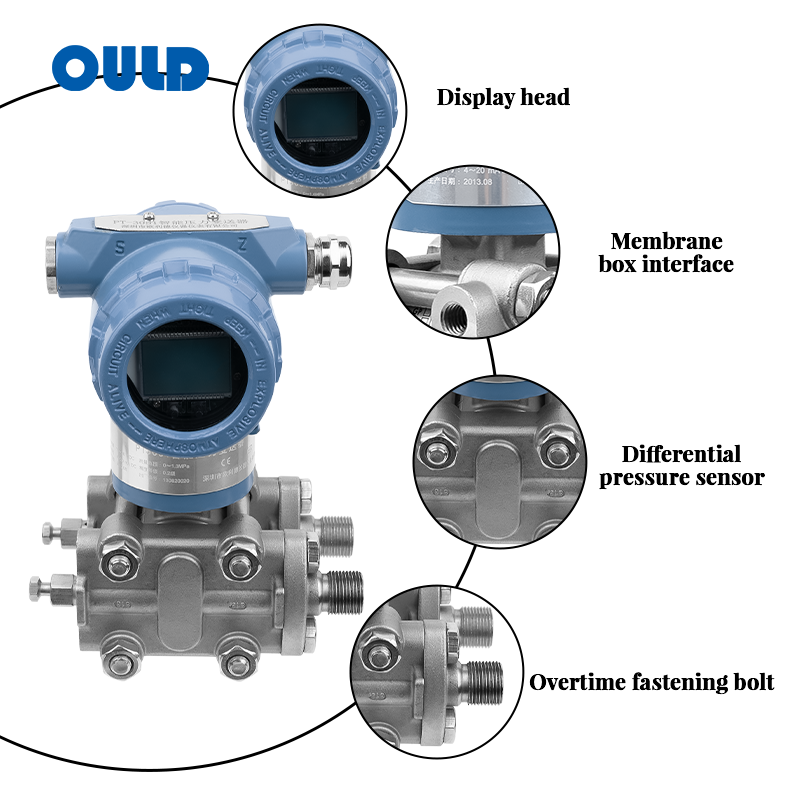

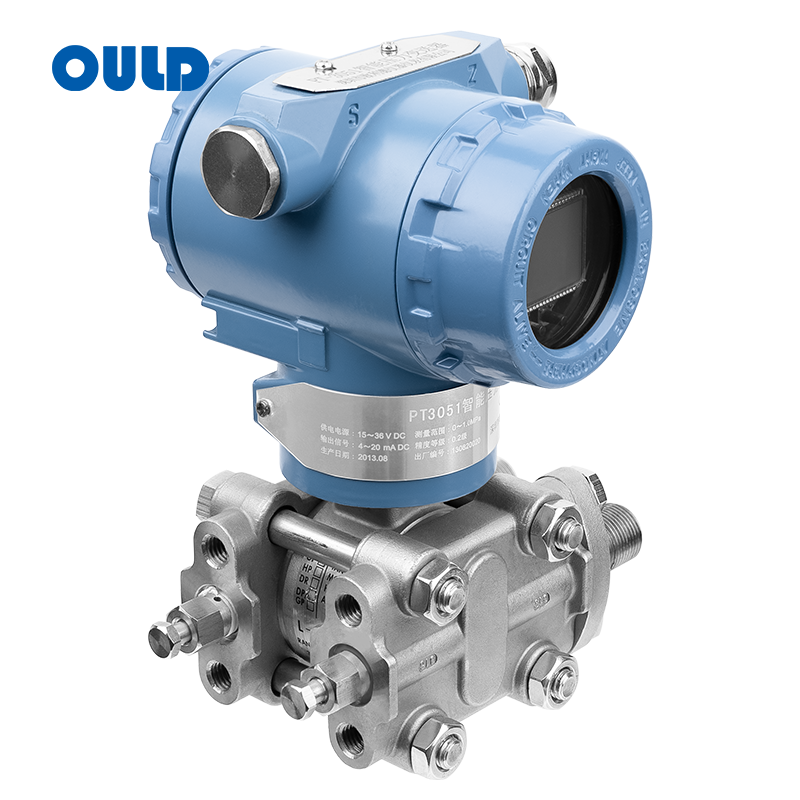

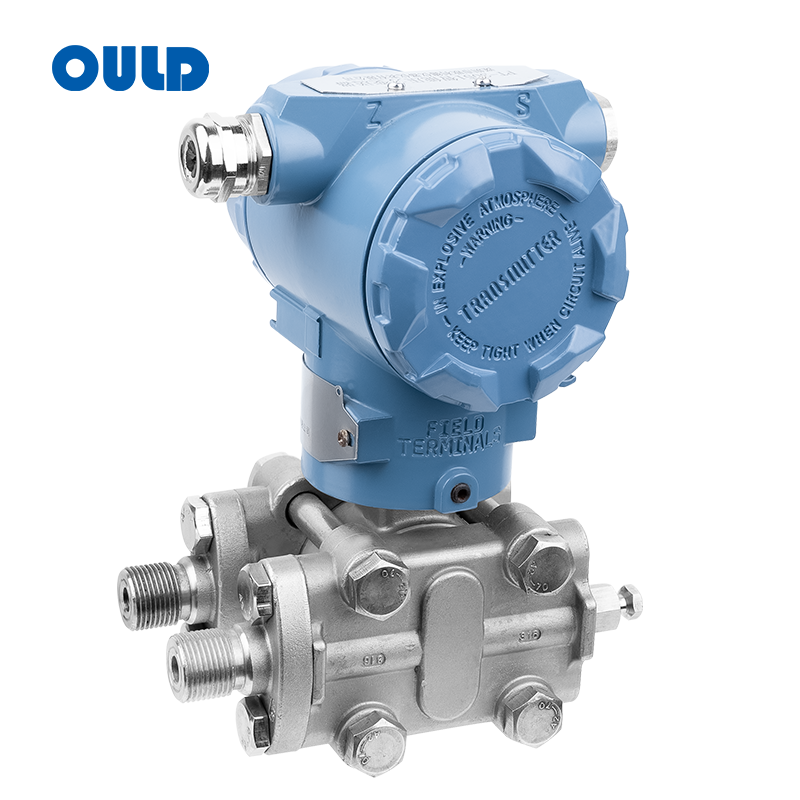

3051 pressure sensor Capacitive high-precision smart pressure transmitter

The PT3051 series capacitive smart transmitter is a high-precision and miniaturized smart sensor produced using advanced foreign technology. In terms of conversion principle, it uses a direct digital capacitive circuit to replace the analog signal amplification circuit and A/D conversion circuit, and uses digital compensation technology to adjust the temperature. , static pressure is compensated, improving measurement accuracy and reducing temperature drift. It has the characteristics of good long-term stability, high reliability and strong self-diagnosis ability. With its extremely high performance-price ratio, it has become a mainstream product in the transmitter market.

3051 Pressure Sensor Features

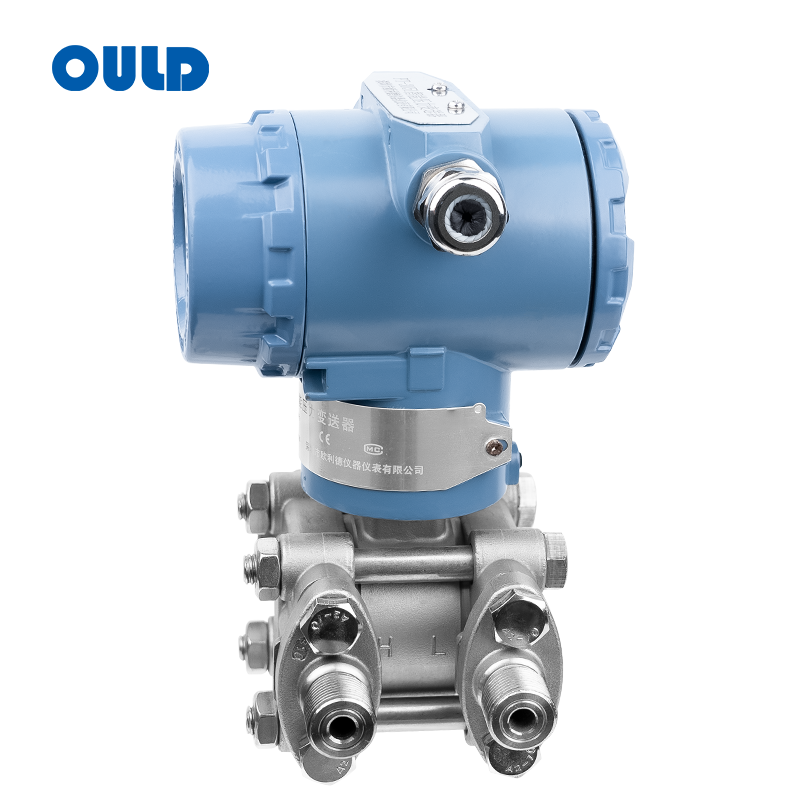

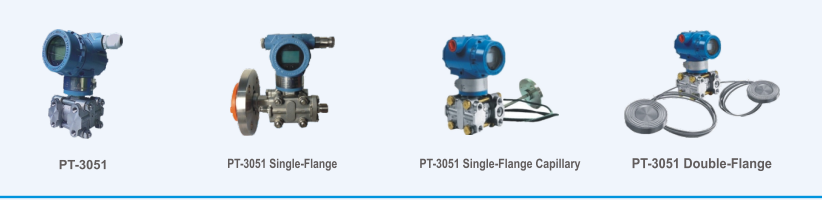

The PT3051 series intelligent transmitter is suitable for measuring flow, liquid level and pressure (gauge pressure, differential pressure, absolute pressure) of liquid, gas and steam media. PT3051 series smart transmitters can be divided into seven varieties according to their uses:

PT3051GP pressure transmitter

PT3051DP differential pressure transmitter

PT3051HP high static pressure differential pressure transmitter

PT3051AP absolute pressure transmitter

PT3051LT liquid level transmitter

PT3051GP remote pressure transmitter

PT3051DP remote differential pressure transmitter

The PT3051 series of smart transmitters not only have the proven characteristics of capacitive sensitive components such as stable performance, high reliability and strong overload resistance, but also add advanced digital compensation and communication functions. This makes the PT3051 series smart transmitter a high-precision smart transmitter with a wide range of uses.

The transmitter can complete testing, configuration, calibration and other functions through our company's HRTMASTER configuration/debugging system, and is also compatible with the ROSEMOUNT275 handheld terminal. Local zero point and span adjustments can be made from the keys in the control room or on the transmitter circuit board through a handheld communicator or debugging equipment.

When performing remote communication, please note: there must be a resistance of no less than 250Ω between the terminal block and the power supply. Before using the HRTMASTER configuration/debugging system to connect to the transmitter, please be sure to read the relevant product manual.

Product advantages

- Increased flexibility and enhanced functions due to the use of microprocessors;

- Has strong self-diagnosis ability;

- Measurement range covers 0-0.2KPa~41.37MPa;

- The accuracy is better than 0.1 level, and the range ratio is better than 40:1;

- Zero point and span adjustment do not affect each other;

- Both remote and local zero point and range adjustment;

- Two-wire system, compliant with HART® protocol, can carry out digital communication with ROSEMOUNT275 without interrupting analog output;

- The sensor has non-volatile memory;

- Good stability, high accuracy, adjustable damping, and strong one-way overload resistance;

- No mechanical transmission parts, less maintenance work, strong and vibration-resistant;

- The display head can be freely rotated 330° to facilitate on-site observation;

- All common parts, sensors and electronic boards are interchangeable without affecting the performance of the transmitter, making maintenance more convenient;

- The diaphragm material in contact with the medium is optional, and the explosion-proof shell structure is available;

Proven superior performance and reliability;

If you are not sure what kind of pressure sensor is right for your project.please contact us

Main performance indicators

Precautions for installation in hazardous locations

In order to maintain the explosion-proof function of the installed transmitter, the following matters must be paid attention to (see the explosion-proof instructions for details).

1. The cover must be tightened to ensure at least 6 engagements, and the threads must not be damaged.

2. The connection between the sensor and the electrical housing must be engaged at least 6 times, and the threads must not be damaged.

3. Wiring holes must be sealed with suitable seals.

4. If the other wiring hole on the housing is not in use, it must be plugged with a threaded metal plug, engaging at least 6 buckles.

PT3051 series intelligent transmitter is suitable for measuring flow, liquid level and pressure (gauge pressure, differential pressure, absolute pressure) of liquid, gas and steam media.