- Introduction

- Technical data

- Electrical connection

- Dimensions

- Applications

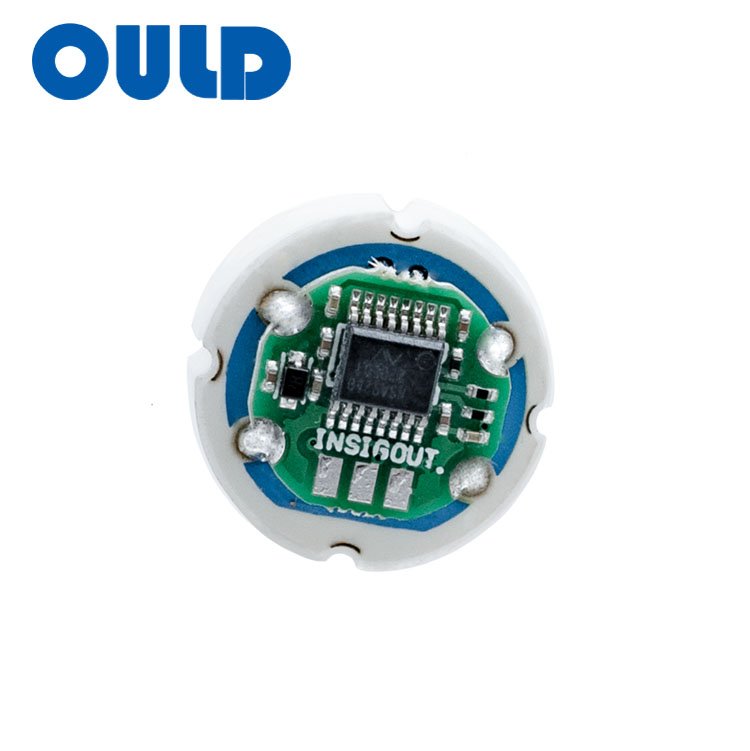

ceramic pressure sensor Core module:

Ceramic pressure sensor Core module The size is 18mm*6.35mm. CP-102 is a temperature and pressure integrated sensor using ceramic (Al2O3 96%) material as the base.

The size is 18mm*6.35mm.The measuring bridge and temperature measuring resistor are directly printed on the ceramic diaphragm through thick film circuit technology, and the other side of the diaphragm is directly in contact with the measured medium.

Due to the good chemical stability of ceramics, the waterproof ring can be used directly to install the sensor on the housing or other accessories without additional protection.

This design also allows the sensor to maintain a high degree of stability during temperature changes and overloads, ensuring high linearity throughout the entire range of the sensor and minimizing the hysteresis effect of pressure.

The good thermal stability of ceramics and the thick-film high-temperature sintering process enable the working temperature range of ceramic pressure sensors to reach -40-125”°C. They have the characteristics of high elasticity, corrosion resistance, and wear resistance.

The high elasticity and creep resistance of ceramics Denaturation gives ceramic pressure sensors good long-term stability. In addition, the corrosion resistance of the sensor gives it unique advantages in fields such as refrigeration, chemical industry, and ecological environment protection.

product development concept

Introducing our cutting-edge Ceramic Pressure Sensor Core Module, a game-changing component designed to revolutionize pressure sensing applications across various industries. This state-of-the-art module is engineered with precision and innovation at its core, making it the ideal choice for demanding and critical environments.

The is meticulously crafted using advanced ceramic materials, guaranteeing exceptional durability, reliability, and accuracy in measuring pressure. This module is finely tuned to deliver precise data readings, ensuring superior performance in a wide range of applications.

Characteristics of living alone

One of the key features of the Ceramic Pressure Sensor Core Module is its versatility. Whether used in automotive, industrial, medical, or environmental monitoring applications, this module excels in providing accurate and real-time pressure measurements. With its compact size and robust construction, it can seamlessly integrate into existing systems, making it a versatile solution for various projects.

Moreover, the Ceramic Pressure Sensor Core Module offers unparalleled sensitivity, allowing for the detection of even the slightest pressure changes with high precision. This level of sensitivity is crucial for applications where precise pressure monitoring is essential for operational efficiency and safety.

In addition to its exceptional performance capabilities, this module is designed for easy installation and integration, saving valuable time and effort during the setup process.Its user-friendly interface and compatibility with a range of communication protocols further enhance its usability and convenience.overall, the Ceramic Pressure Sensor Core

Module sets a new standard in pressure sensing technology, providing unmatched reliability, accuracy, and performance.Whether you are looking to enhance your existing pressure monitoring system or develop a new cutting-edge application, this module is the perfect choice to meet your requirements.

Invest in the today and experience the future of pressure sensing technology. Upgrade your systems with this innovative module and take your projects to new heights of efficiency and accuracy.

Trust in the reliability and precision of our Ceramic Pressure Sensor Core Module – the ultimate solution for all your pressure sensing needs.

main feature:

High cost performance

High linearity

High burst pressure

wide temperature range

The temperature measuring resistor responds quickly

Good long-term stability

Easy to install

FAQ:

Q: Are you manufacturer or trading company?

A: We are leading manufacturer for pressure sensors, pressure transmitters, temperature sensors, temperature transmitters, wireless pressure transmitters, and level transmitters for more than 22 years.

Q: Do you accept OEM production?

A: Yes, we also do customized products, customized pressure range, output signals, housing, logo, etc. Normally, we will have requirement on MOQ for customized products.

Q: Can I get samples?

A: Yes, we will be glad to provide you samples as per your specific technical requirements.

Q: What is the lead time for your products?

A: For the products we have in stock, our lead time is immediate shipment after payment. For the products of no stock, our lead time is 1-2 weeks after payment.

Contact us for more product information

Bridge Resistance | 11±30%KΩ |

Power Supply | 2-30V |

Pad | PdAg |

Response time | <1ms |

Zero Point Signal | ±0.2mV/V |

Full point Signal | 1.5~4mV/V |

Comprehensive Accuracy (Linearity, Hysteresis, Repeatability) | ±0.5% |

Long-term Stability | ±0.3%/year |

Temperature Range | -40~125℃ |

Temperature Drift | ±0.03%/℃ |

Insulation Resistance @25℃,85%RH,500VDC | 100M |

Weight | ≤7g |

Pressure Range (bar) | Overload Pressure (bar) | Burst Pressure (bar) |

2 | 4 | 6 |

5 | 10 | 15 |

10 | 20 | 30 |

20 | 40 | 60 |

30 | 60 | 90 |

50 | 100 | 150 |

100 | 200 | 300 |

200 | 400 | 500 |

400 | 600 | 700 |

Ceramic Pressure Sensor is widely used in process control, environmental control, hydraulic and pneumatic equipment, servo valves and transmission, chemical and chemical industry and medical instruments and many other fields.