- Introduction

- Technical data

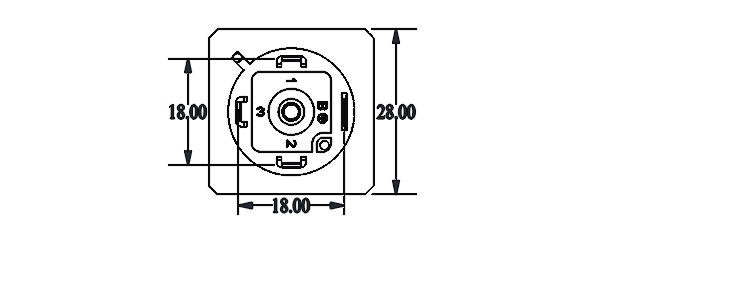

- Electrical connection

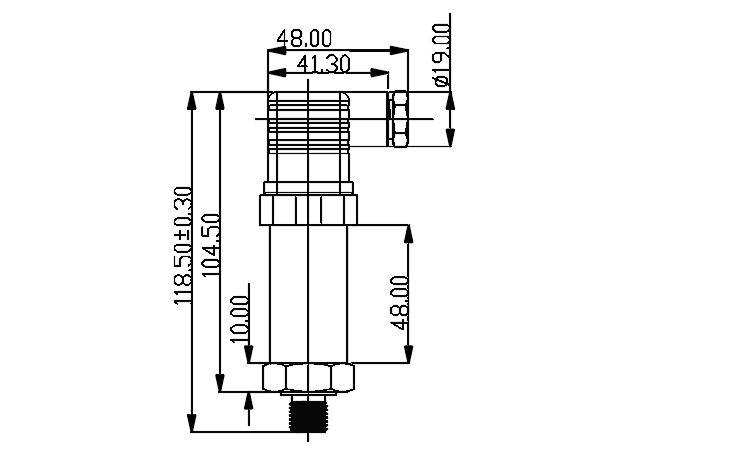

- Dimensions

- Applications

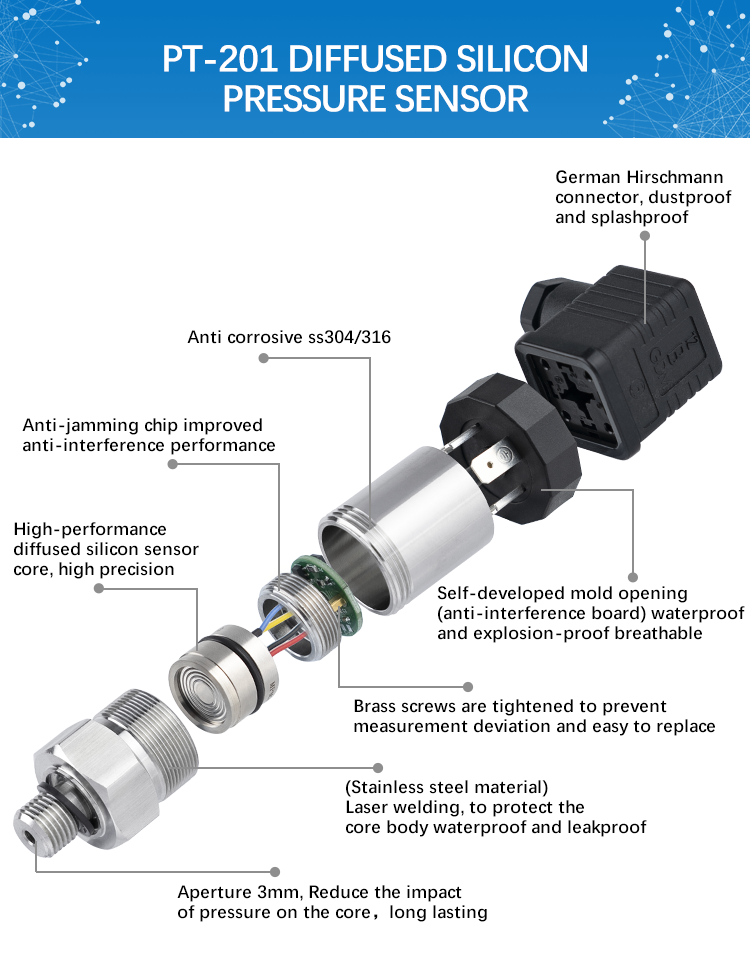

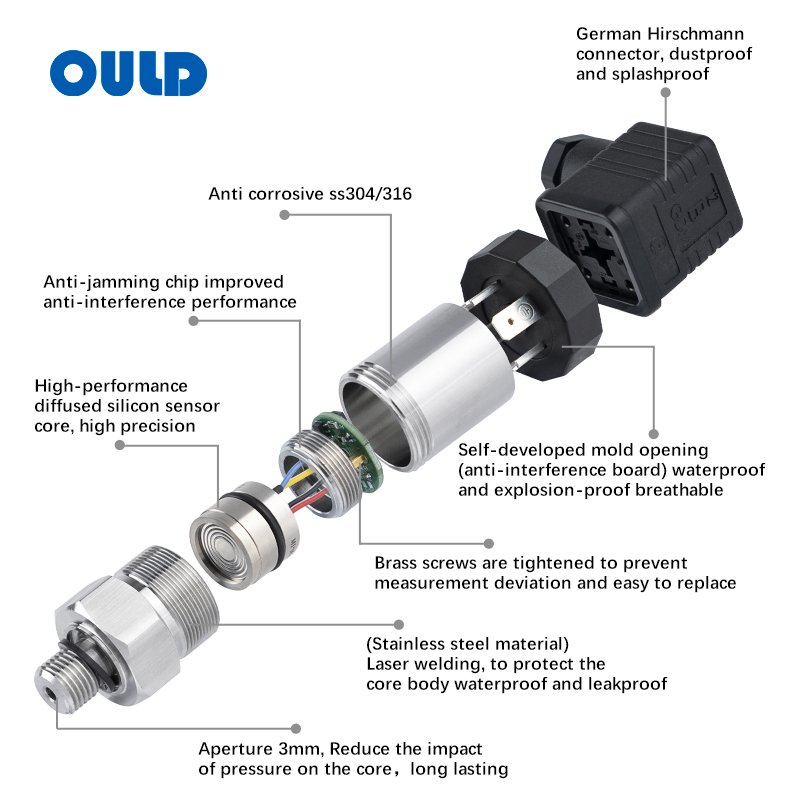

PT-201 Industrial Universal Diffused Silicon Pressure Sensor

PT-201 Industrial Universal Diffused Silicon Pressure Sensor Adopts diffused silicon pressure sensor core from an internationally renowned company, through high-reliability amplification circuit and precision digital temperature compensation and non-linear correction technology, the pressure of the measured medium is converted into 4~20mA, 0~10VDC analog signals and IIC, RS485, etc.Standard digital signal.Coupled with the versatile Herschmann plug, it ensures excellent product quality and optimal performance.Can measure the pressure of various fluids conveniently, quickly and accurately

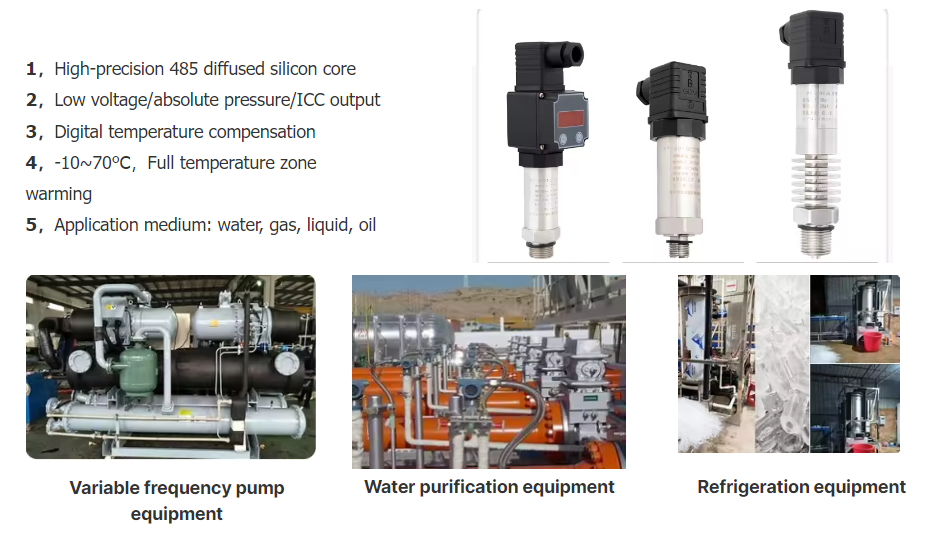

Scope and fields of use

1. Industrial Automation

2. Hydraulic Systems

3. HVAC Systems

4. Process Control

Pressure Monitoring in Manufacturing The PT-201 Industrial Universal Diffused Silicon Pressure Sensor is the ideal solution for industrial applications where precise pressure measurements are essential. Trust in its reliability and accuracy to meet your industrial requirements.

Diffused Silicon Pressure Sensor Features:

- The high-performance diffused silicon sensor core is equipped with a highly integrated bridge pressure sensor dedicated advanced chip for signal conditioning.

- Digital temperature compensation and non-linear correction

- A variety of signal outputs, with waterproof and breathable plugs, suitable for conventional sockets such as Hirschmann and HTP

- High sensitivity, high precision, high stability

- Full temperature zone temperature compensation, good electrical performance and long-term stability

- Process connections can be customized

- High cost performance, one year warranty

Selection tips:

1. When selecting, please note that the medium to be measured must be compatible with the part of the product that is in contact with the medium.

2. Voltage input and output have various ranges, which need to be specified in the order.

3. The process connection can be customized and needs to be specified in the order.

4. The IIC output type has no polarity protection. The installation and use process must be confirmed before powering on.

5. For special requirements, please discuss with our company and indicate them in the order.

Purchase guide

To recommend you the most suitable sensor, please tell us below information.

1. Working temperature: -40~+125 °C ?

2. Test range?

3. Output: 4-20mA , RS485 or others?

4. Screw: G1/4, 1/4NPT, R1/4, M20*1.5?

5. Electrical connection: Packard, Direct lead?

6. Order quantity: ?

7.Apploed equipment?

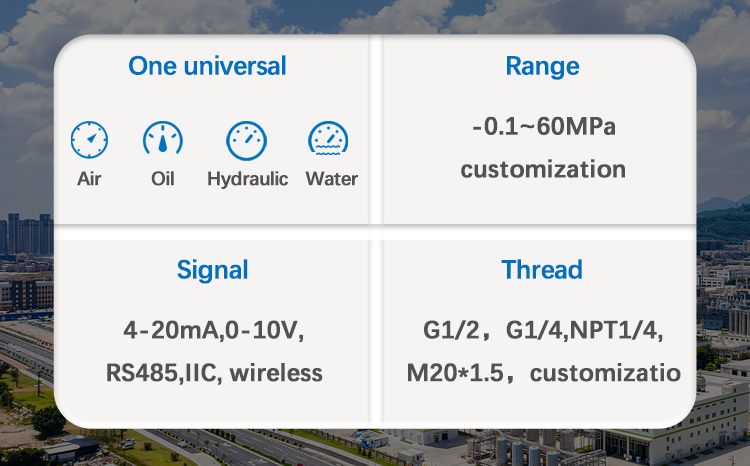

Measuring range | -1…0~0.1…700Bar | |||

overload pressure | 200%FS | |||

process connection | G1/4, etc., can be customized | |||

Comprehensive accuracy | ±0.5% | |||

temperature drift | ±0.03%/℃ | |||

Temperature compensation range | -10~70℃ | |||

long term stability | ±0.3%FS/year | |||

Operating temperature | -40~85℃ | |||

Storage temperature | -40~125℃ | |||

output signal | Absolute value 0-10V | Scale 0-5V | 4-20mA | IIC/485 |

Supply voltage(V) | 10-36 | 3.0-5.5 | 10-36 | 3.3-5.5/10-36 |

load(2) | >10K | >10K | ≤50(U-10) | / |

Protection level | IP65 | |||

Media adaptability | Various fluids that are non-corrosive to 304 stainless steel | |||

vibration | 10gRMS,(20~2000)Hz | |||

impact | 100g,11ms | |||

insulation | Greater than 100MΩ @250VDC | |||

Response time | Less than 1ms | |||

Electrical connections:

| Output definition | 4~20mA | Vout | IIC | RS485 |

| 1 | Vin(red) | Vin(red) | Vin(red) | Vin(red) |

| 2 | GND(black) | GND(black) | SCL(White) | A(yellow) |

| 3 | Vout(white) | SDA(yellow) | B(white) | |

| 4 | GND(black) | GND(black) |