- Introduction

- Technical data

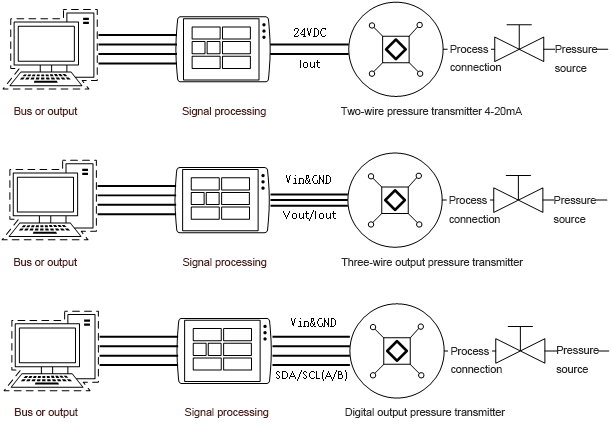

- Electrical connection

- Dimensions

- Applications

PT-928 input level transmitter uses the diffusion silicon pressure sensor core of an internationally renowned company. After a high-sensitivity amplifier circuit, accurate digital temperature compensation, and nonlinear correction technology, the measured liquid depth is converted into 4~20mA, 0~10VDC analog signal, and IIC, RS485, and other standard digital signals. Fully sealed 304 stainless steel structure, protection grade IP68. Users can easily, quickly, and accurately measure the height of various liquids. Ultra-high cost performance can be widely used in petroleum, chemical, metallurgy, electric power, water supply, and other fields.

PT-928 Input Level Transmitter Features

- The high-performance diffused silicon sensor core is equipped with a highly integrated bridge-type pressure sensor signal conditioning dedicated to advanced chips.

- Digital temperature compensation and nonlinear correction.

- Multi-signal output, equipped with air-permeable cable: perfectly solve the gauge pressure error between the sensor and the atmosphere.

- High sensitivity, high precision, and high stability.

- Comprehensive temperature compensation, good electrical performance, and long-term stability.

- The liquid inlet is equipped with a protective cover, which is easy to clean and can effectively protect sand and sediment.

- Can be customized according to customer needs and OEM/laser marking.

- High-cost performance, one year warranty.

If you are interested in our products, please contact us.

| Range | 0-1000m | ||||

| Overload Pressure | 200%FS | ||||

| Process Connection | M20*1.5 | ||||

| Comprehensive Accuracy | ±1%、±0.5%、±0.2%、±0.1% | ||||

| Operating Temperature | -40℃~85℃ | ||||

| Temperature Drift | ±0.03%/℃ | ||||

| Temperature Compensation Range | -10~70℃ | ||||

| Long-term Stability | ±0.3%FS/year | ||||

| Storage Temperature | -40~125℃ | ||||

| Supply Voltage | 10-36 | 3.0-5.5 | 10-36 | 3.3-3.5 | 10-36 |

| Output Signal | Absolute value 0-10V | Scale 0-5V | 4-20mA | IIC | RS485 |

| Load (Ω) | >10k | >10k | ≤50 (U-10) | - | - |

| Protection class | IP68 | Sealing ring | Nitrile rubber | ||

| Media adaptability | Non-corrosive fluids | ||||

| Vibration | 10gRMS, (20~2000)Hz | ||||

| Shock | 100g, 11ms | ||||

| Insulation | Greater than 100MΩ @250VDC | ||||

| Response time | Less than 1ms | ||||

| CE certification | EMC: IEC61326-1 Class B | ||||

| Electrostatic discharge immunity: IEC61000-4-2 | |||||

| Electromagnetic field immunity: IEC61000-4-3 | |||||

| EFT immunity: IEC61000-4-4 | |||||

| Surge immunity: IEC61000-4-5 | |||||

| Output Definition | 4~20mA | Vout | IIC | RS485 |

| ① | Vin (Red) | Vin (Red) | Vin (Red) | Vin (Red) |

| ② | GND (Black) | GND (Black) | SCL (White) | A (Yellow) |

| ③ | Vout (White) | SDA (Yellow) | B (White) | |

| ④ | GND (Black) | GND (Black) |

PT-219 Selection Tips

1. When choosing a model, please note that the measured medium should be compatible with the part of the product that is in contact with the medium, and the specific gravity of the measured medium must be indicated (the default is water 1g/cm³, T = 4°C).

2. There are multiple ranges of voltage input and output, which need to be indicated in the order.

3. IIC output type has no polarity protection, and the power supply must be confirmed after installation and use. The cable length is less than 3 meters.

4. During the installation process, the cable should not be bent vertically but should be bent into an arc, so as not to block the air guide hole and affect the accuracy.

5. When measuring the flowing liquid, a hard tube of about φ50 can be inserted into the liquid, and several small holes can be opened at different heights in the opposite direction to the water flow to avoid the influence of the liquid on the pressure.

6. When installing products in thunderstorm areas, it is recommended that users install lightning protection equipment.

7. If you have special requirements, please consult our company and indicate in the order.

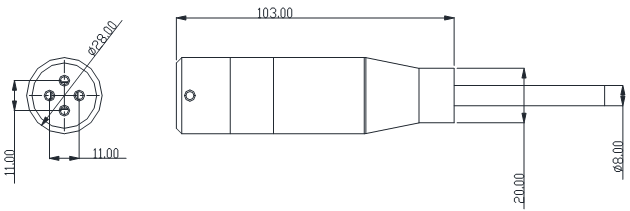

PT-928 Dimension

Input level transmitter used in water monitoring.