- Introduction

- Technical data

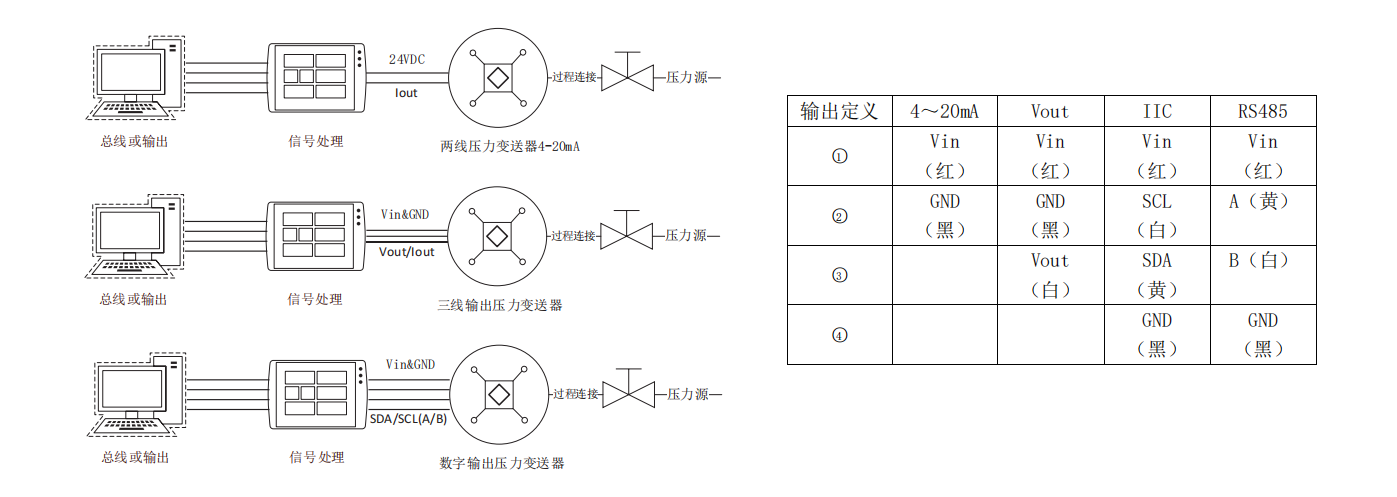

- Electrical connection

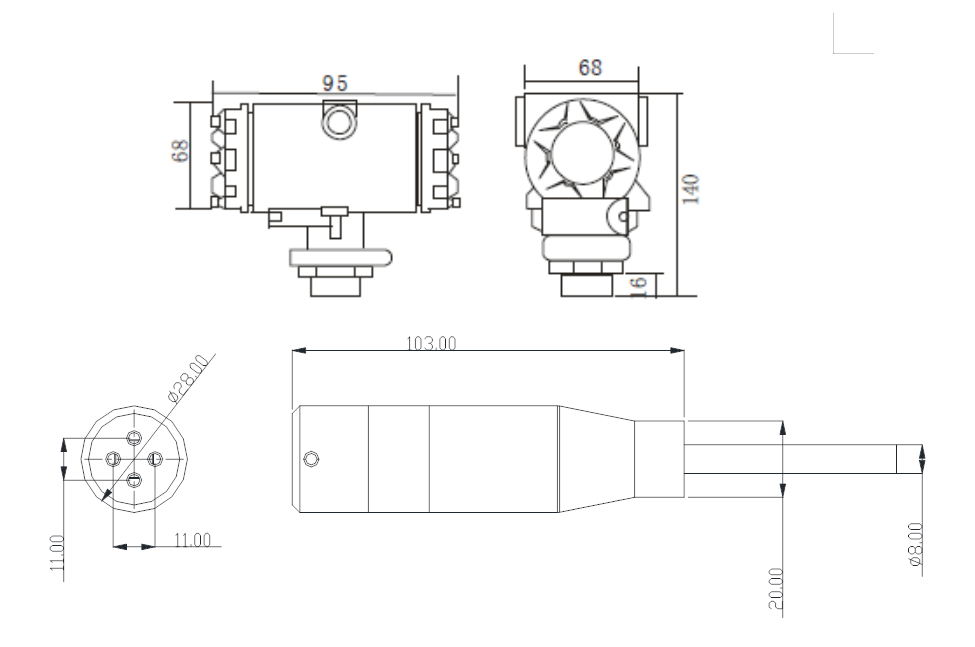

- Dimensions

- Applications

Liquid level pressure sensor high accuracy 4-20mA for water Tanks and Deep Well Pump

Liquid level pressure transmitter sensor PT-928 adopts the diffused silicon pressure sensor core of an internationally renowned company. It converts the measured liquid depth into 4~20mA through a highly reliable amplification circuit and precise digital temperature compensation and non-linear correction technology. , 0~10VDC analog signal and IIC, RS485 and other standard digital signals. It has a wide measuring range and a variety of output signals. Good stability over a wide temperature range. Fully sealed 304 stainless steel isolated small structure, protection grade IP68. Users can measure the height of various liquids conveniently, quickly and accurately. The ultra-high cost performance can be widely used in water conservancy monitoring, underwater environmental work, tap water pipeline systems, underground water pipeline pressure measurement, industrial process pressure measurement and other fields. Can be customized and OEM manufactured according to needs.

Liquid level pressure transmitter sensor features

- Compact design, laser welding sealing method;

- Stable sensor core, high cost performance;

- IP68 waterproof all-stainless steel housing;

- Waterproof and anti-corrosion gas cable export;

- High sensitivity, high precision, high stability.

- A variety of pressure interfaces and signal outputs are available.

- Digital temperature compensation and non-linear correction

- The liquid inlet is equipped with a protective cover for easy cleaning and can effectively protect against sand, gravel and sedimentation

- Multiple signal outputs, equipped with breathable cables: perfectly solve the gauge pressure error caused by the disconnection between the sensor and the atmosphere.

- The high-performance diffused silicon sensor core is equipped with a highly integrated bridge pressure sensor dedicated advanced chip for signal conditioning.

- High cost performance, one-year warranty

ABOUT US

More product recommendations

If you are interested in our products, please contact us.

| Range | 1000m | ||

| Type of Pressure | Gauge pressure, absolute pressure | ||

| Overload Pressure | 200%FS | ||

| Process Connection | G1/4, G1/2, M20*1.5, 1/4NPT, R1/4 can be customized | ||

| Comprehensive Accuracy | ±1%FS,±0.5%FS、±0.2%FS、±0.1%FS | ||

| Temperature Compensation Range | ±0.3%FS/year | ||

| Long-term Stability | -10~70℃ | ||

| Operating Temperature | -40℃~85℃ | ||

| Storage Temperature | -40℃~125℃ | ||

| Protection Level | IP68 | ||

| Supply voltage (DC) | 10-36V | 3-5V | |

| Output Signal | 4-20mA | 0-5V | 0-5V |

| Load Resistance | 50 (U-10)Ω【4-20mA】, greater than 10KΩ【V】 | ||

| Material | Sensor: ceramic; housing: stainless steel 304; cable: PVC; waterproof ring: HNBR | ||

| Medium Adaptability | Various fluids that are non-corrosive to 304 stainless steel | ||

| Vibration | 10gRMS, (20~2000)Hz | ||

| Shock | 100g, 11ms | ||

| Insulation | Greater than 100MΩ @250VDC | ||

| Response Time | Less than 1ms (@90%FS) | ||

| CE Certification | EMC: IEC61326-1 Class B | ||

| Electrostatic discharge immunity: IEC61000-4-2 | |||

| Electromagnetic field immunity: IEC61000-4-3 | |||

| EFT immunity: IEC61000-4-4 | |||

| Surge immunity: IEC61000-4-5 | |||

Selection tips:

1. When selecting, please note that the medium to be measured must be compatible with the part of the product that is in contact with the medium. At the same time, the type of the medium to be measured must be noted.

Specific gravity (default is water 1g/³ T=4℃).

2. Voltage input and output have various ranges, which need to be specified in the order.

3. IIC output type has no polarity protection. The installation and use process must be confirmed before powering on. The wire length is less than 3 meters.

4. The cable must not be bent vertically during installation, but must be bent in an arc to avoid clogging the air guide holes and affecting accuracy.

5. When measuring flowing liquid, you can insert a hard tube of about φ50 into the liquid, and open a number of small holes at different heights in the opposite direction of the water flow in the tube to avoid the impact of liquid flow on the pressure.

6. When the product is installed in an area with frequent thunderstorms, it is recommended that the user install a lightning protection device.

7. For special requirements, please consult with our company

The PT-928 input liquid level transmitter adopts the diffused silicon pressure sensor core of an internationally renowned company. It converts the measured liquid depth into 4~20mA through a highly reliable amplification circuit and precise digital temperature compensation and non-linear correction technology. , 0~10VDC analog signal and IIC, RS485, etc.

Standard digital signal. Fully sealed 304 stainless steel structure, protection grade IP68. Users can measure the height of various liquids conveniently, quickly and accurately. It is extremely cost-effective and widely used in water conservancy monitoring, underwater environmental work, tap water pipeline systems, underground water pipeline pressure measurement, industrial process pressure measurement, etc.