- Introduction

- Technical data

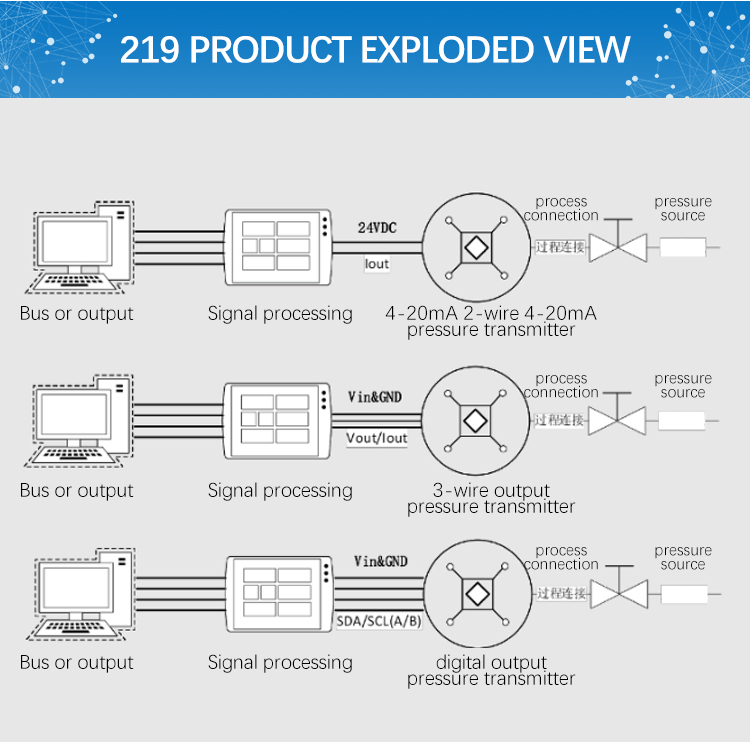

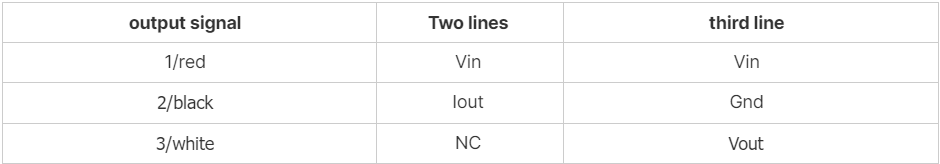

- Electrical connection

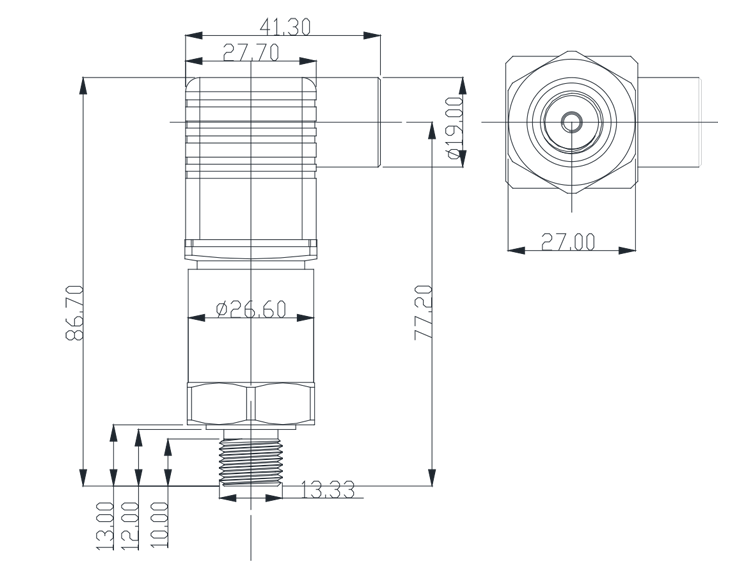

- Dimensions

- Applications

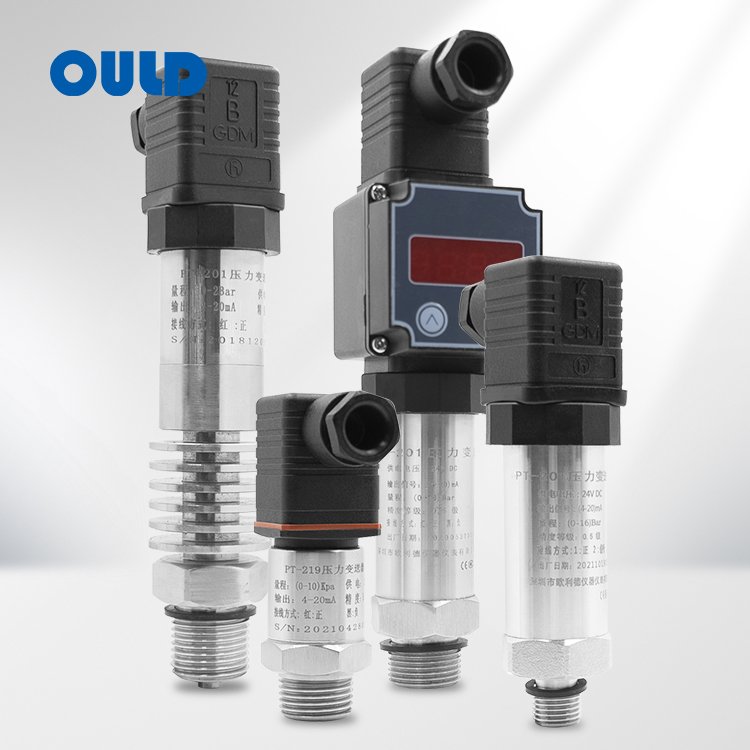

Universal industrial 4-20mA output 0-10v RS485 low cost gas water Liquid pressure sensor

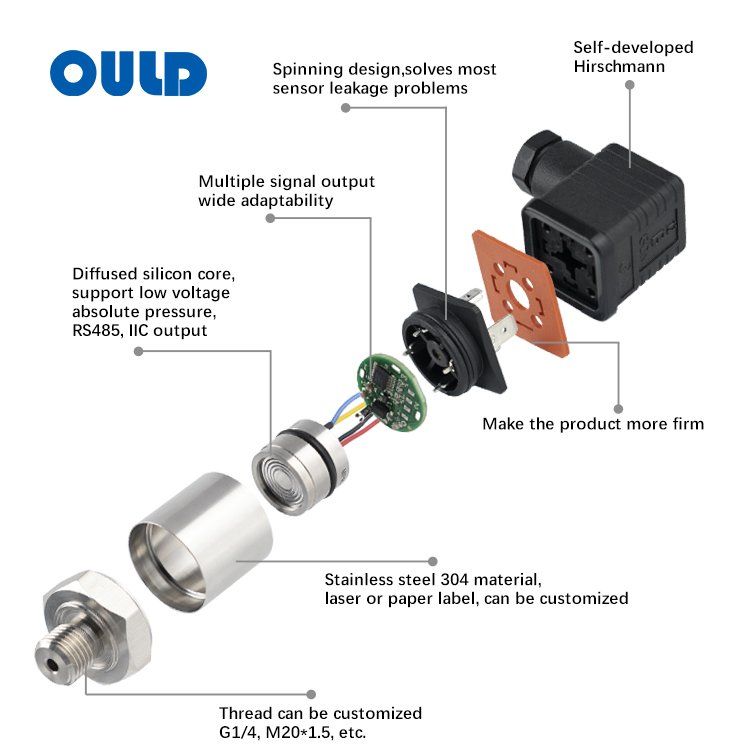

The PT-219 Low cost gas water Liquid pressure sensor transmitter adopts the diffused silicon pressure sensor core of an internationally renowned company. It converts the pressure of the measured medium into 4~20mA, 0 ~10VDC analog signal and IIC, RS485 and other standard digital signals.

Low cost gas water Liquid pressure sensor transmitter use the independently molded waterproof plug and fully sealed welding process ensure the product's excellent quality and optimal performance. Users can conveniently, quickly and accurately measure the pressure of various fluids. The ultra-high cost performance can be widely used in petroleum, chemical industry, metallurgy, electric power, variable frequency pumps, complete water supply, refrigeration, air conditioning, air compressors and other fields.

PT-219 water Liquid pressure sensor transmitter characteristics

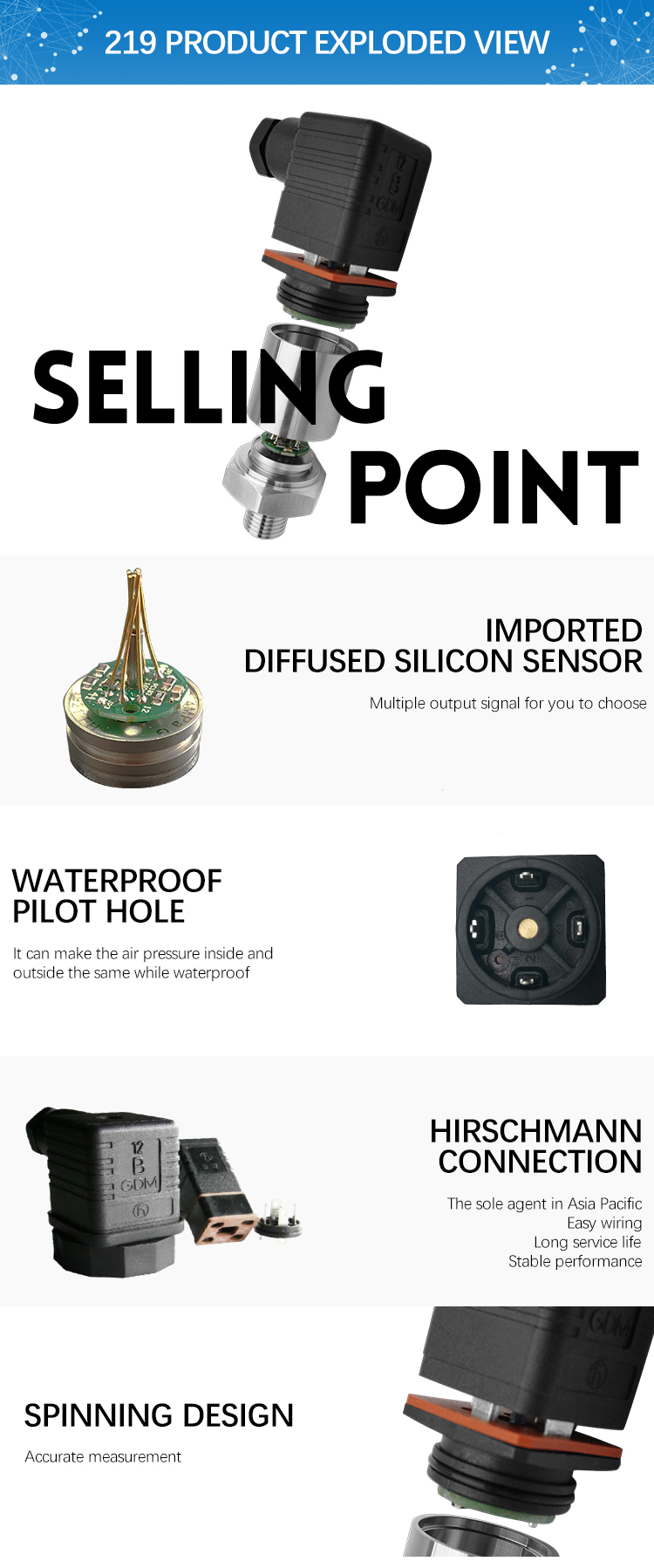

• The high-performance diffused silicon sensor core is equipped with a highly integrated bridge pressure sensor dedicated advanced chip for signal conditioning

• Digital temperature compensation and non-linear correction

• Multiple signal outputs, equipped with self-molded plugs that are waterproof and breathable, perfectly adaptable to conventional sockets such as Hirschmann and HTP, and are widely applicable

• High sensitivity, high precision, high stability

• Full temperature zone temperature compensation, good electrical performance and long-term stability

• The plug and shell are integrally spun to be stable, reliable and waterproof, preventing the threads of ordinary plugs from loosening.

• Process connections can be customized

• High cost performance, one-year warranty

Selection tips

1. When selecting, please note that the medium to be measured must be compatible with the part of the product that is in contact with the medium.

2. Voltage input and output have various ranges

3. Process connection can be customized

4. The IIC output type has no polarity protection. The installation and use process must be confirmed before powering on.

5. For special requirements, please consult with our company.

If you want to know more, you can leave us a message

| Measuring range: | -1~100Bar |

| Overload pressure: | 200%FS |

| Process connection: | G1/4, etc., can be customized |

| Comprehensive accuracy: | ±0.5%, ±0.2%, ±0.1% |

| Temperature drift: | ±0.03%/℃ |

| Temperature compensation range: | -10~70℃ |

| Long-term stability: | ±0.3%FS/year |

| Working temperature: | -40~85℃ |

| Storage temperature: | -40~125℃ |

| Output signal: | absolute value 0-10V/ratio 0-5V/4-20mA/IIC/RS485 |

| Supply voltage (V): | 10-36/3.0-5.5/10-36/3.3-5.5/10-36 |

| Load (Ω): | >10K/>10K/≤50(U-10) |

| Protection level: | IP65 |

| Vibration: | 10gRMS, (20~2000)Hz |

| Impact: | 100g, 11ms |

| Insulation: | greater than 100MΩ @250VDC |

| Response time: | less than 1ms |

| CE certification: | EMC: IEC61326-1 Class B |

| Electrostatic discharge immunity: IEC61000-4-2 | |

| Electromagnetic field immunity: IEC61000-4-3 | |

| EFT immunity: IEC61000-4-4 | |

| Surge immunity: IEC61000-4-5 |

Can be widely used in petroleum, chemical industry, metallurgy, electric power, variable frequency pumps, complete water supply, refrigeration, air conditioning, air compressors and other fields.