Cause of Short/Open Circuit in Pressure Transmitter for Process Control

Guide for Pressure Transmitter for Process Control

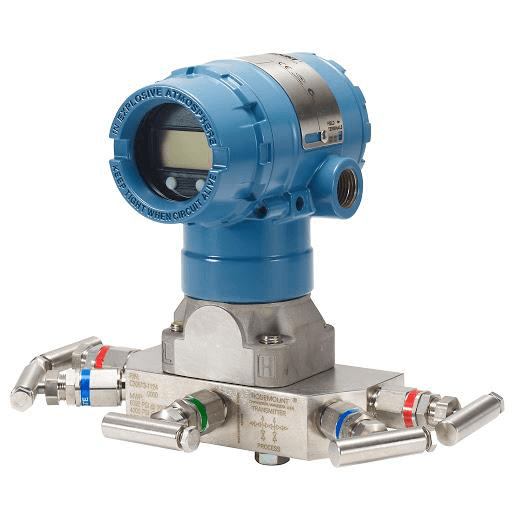

Every manufacturing company makes use of a pressure transmitter for process control at one point or another. They have become a pre-requisite for performing any manufacturing procedure. In this competing industry, it is very important to own leverage.

Pressure transmitters for process control can provide that leverage. It is not as much of a secret but a way of manufacturing. To run a successful industrial business they have become a necessity. Pressure transmitters have become popular over time because of their outstanding features.

You May Also Read: Guide to a Pressure Transmitter For Hygiene Industry Technology

To ensure that the manufacturers are giving their best, it is important to attain the right kind of tools, maintain the right environment along with the installation of advanced gadgets like Pressure transmitters for process control. They have proven to reduce cost and time thus giving better production results.

Use of Pressure Transmitter for Process Control

When manufacturing, the companies have to deal with a variety of elements during process control. Some are in the form of solids; others are in the form of liquids as well as gases. These elements are processed at different temperatures and in different quantities using a Pressure transmitter for process control.

Industrial operations cannot do without pressure transmitters. It is an integral part of the whole production line. They have proved to be handy in performing biochemical procedures too. Transmitters play a vital role in catering to the symmetrical needs in chemical and liquid transactions.

Along with the use of a Pressure transmitter for process control, they help create a safe working environment too. Safety is an initial and the most important part of any manufacturing plant. Transmitters are a great way to manage this possibility.

Pressure transmitters usually consist of sensors and diaphragms. When signaled, these transmitters receive electric motions. Secondary sensors create these motions. It bases on a complex setup of hardware that performs the given tasks. These transmitters follow the specified instructions and thus notify the personnel when something unusual likely happens.

Cause of Short Circuit or Open Circuit in Pressure Transmitter for Process Control

There can be very evident and noticeable reasons as to why there is a short or open circuit in the Pressure transmitter for process control. When the machines are running there may be a chance of an alien occurrence like a short circuit or an open circuit.

Whenever there is such an occurrence there are a few immediate steps that can lead to the reason, why the short or open circuit occurred. The very first reason that might cause an open/short circuit is the internal temperature of the environment that surrounds the pressure transmitter. If the temperature sensors detach from the main transmitter, it may cause a short circuit.

Along with checking the external attachments, do give a look over to the sensor panel. It is likely that the sensor panel is damaged during the pressure process. This can cause damage to the display screen of the transmitter along with the panel affecting the circuit.

You May Also Read: The Accuracy Components of Pressure Transmitter for Hygiene Industry

When the sensor panel gets damaged, it may lead to faulty communication between the sensor and the motherboard of the transmitter. This causes a disconnection amongst the external and internal panels of the transmitters which in turn may cause an open or short circuit.

Another major reason behind a short/open circuit is that that the plugs are loose. A loose plug can be very dangerous for the entire process. This can affect the electronic representation of the pressure transmitter.

This might seem a mundane problem which it is but if not controlled/corrected within time can cause major damage to the transmitter and even the whole manufacturing unit. There are very few reasons that can cause a short or open circuit.

It is simple to deal with this issue by just keeping a few points in mind. Temperature sensors are always the first to get affected by an open/short circuit. Hence they often show predictions that there might be some problem with the process. As soon as you see unusual temperature readings or imperfection in production do not wait for the process to complete.

Contact the manufacturer so that the pressure transmitter can repair within time before it causes much more damage. This is a healthier choice for the process controls and for the company overall. Therefore, it is important to track the transmitter readings for effective damage control.

Maintaining Pressure Transmitter for Process Control

Pressure transmitter for process control is one of the best finds by the researchers for manufacturing purposes. They are further working on an advanced pressure transmitter that carries the banner of work safety in the first place.

Pressure Transmitters can handle high temperatures to a certain degree. After reaching the peak limit it becomes necessary to cool them down. When their installation is done inappropriately, they can cause serious harm like a short or an open circuit. It can be harmful to both the industry and humans around them.

Researchers work on the advanced levels of Pressure Transmitters that enable compensating the penalties of high-temperature intensities. Artificial Intelligence is playing a major role to achieve this stance in the manufacturing industry. Pressure Transmitters that can withstand high temperatures as well as are adjustable with the environmental changes are mostly preferred.

The maintenance team needs to make sure that the following features are in mind for the proper functioning of a pressure transmitter.

Choosing the Right Pressure Transmitter for Process Control

It is vital to find the right pressure transmitter for process controls. This is important to ensure plant and worker safety. It is also important to understand that the internal working of the industrial environment affects transmitters. To optimize the results always optimize the setup that you choose to install.

Installing Pressure Transmitter for Process Control

Installation is another major factor that is directly proportional to the safety around the pressure transmitters. The placement of the transmitters should take proper care and planning to maximize the benefits of installing pressure transmitters for process controls. Since they are a key component in any process control the installation needs important brooding.

Maintaining Pressure Transmitter for Process Control

The pressure transmitters that work for process controls do a very rigorous and tough job. They are so worked out that proper maintenance is a necessity if you want the transmitters to retain their initial qualities.

They have to deal with high temperatures, pressures, and levels on a constant basis. It is not surprising that they can wear out in no time if proper maintenance is not given. All to avoid open or short circuits this is an important step.

Results

It is safe to say that the Pressure Transmitter that manufacturers, such as Ould Sensor, use for Process Controls is the heart of the manufacturing industry. They have to go through extreme conditions to give results. These conditions can vary from high temperatures to gas and liquid exposures.

Hence it is important for the manufacturing companies to maintain the working of transmitters. This will prevent the occurrence of any unseen conditions like a short or an open circuit. To prevent these occurrences regular maintenance becomes necessary. A dedicated team to work on the transmitter’s maintenance is also a good idea.

For more information, Contact Us Today.