Design Architecture of Pressure Transmitter for Printing System

Pressure Transmitter for Printing System

Elements around the transmitter for printing system.

With the help of Transmitter for Printing Systems, we now can enjoy outstanding, advanced, and sophisticated printed techniques and technology. These modern technologies offer a number of benefits when it comes to Printed Circuit Boards.

In this article, we are going to highlight the impact of transmitters on printing systems.

Commuting with Transmitter for Printing System

Wireless technology has encompassed unimaginable lengths that include transforming conventional printing systems into futuristic prototypes. The only catch is that this previously unperceived technology has transpired into making a transmitter for printing systems and doing so with the inclusion of radiofrequency.

Printed circuit boards are extensively employed in the manufacturing of countless electronically dependent machines. They have inarguably changed the face of the microelectronics industry. The means of operating on a printed circuit board primarily comprises of the circuit board enabling a printing process through a receiver and transmitter.

In any case, wireless printers have eradicated the need to have hefty material around printer location. It is difficult to comprehend the inner workings of a circuit board however wireless printing has revolutionized the way we commute forever.

The methodology of the Printed Circuit Board

Typically, the manner of operating a circuit board consists of the circuit board that mounts or strategically places inside a printer. The manufacturer attaches two systems to two chips positioned on the circuit board.

Both chip one and chip two have their own parts i.e. receiver, transmitter, and the first processing module, second processing module respectively. At this point, it is critical to mention the significance of radiofrequency in transmitting a data signal through the first processing module. This eventually would lead up to the printing process that would execute.

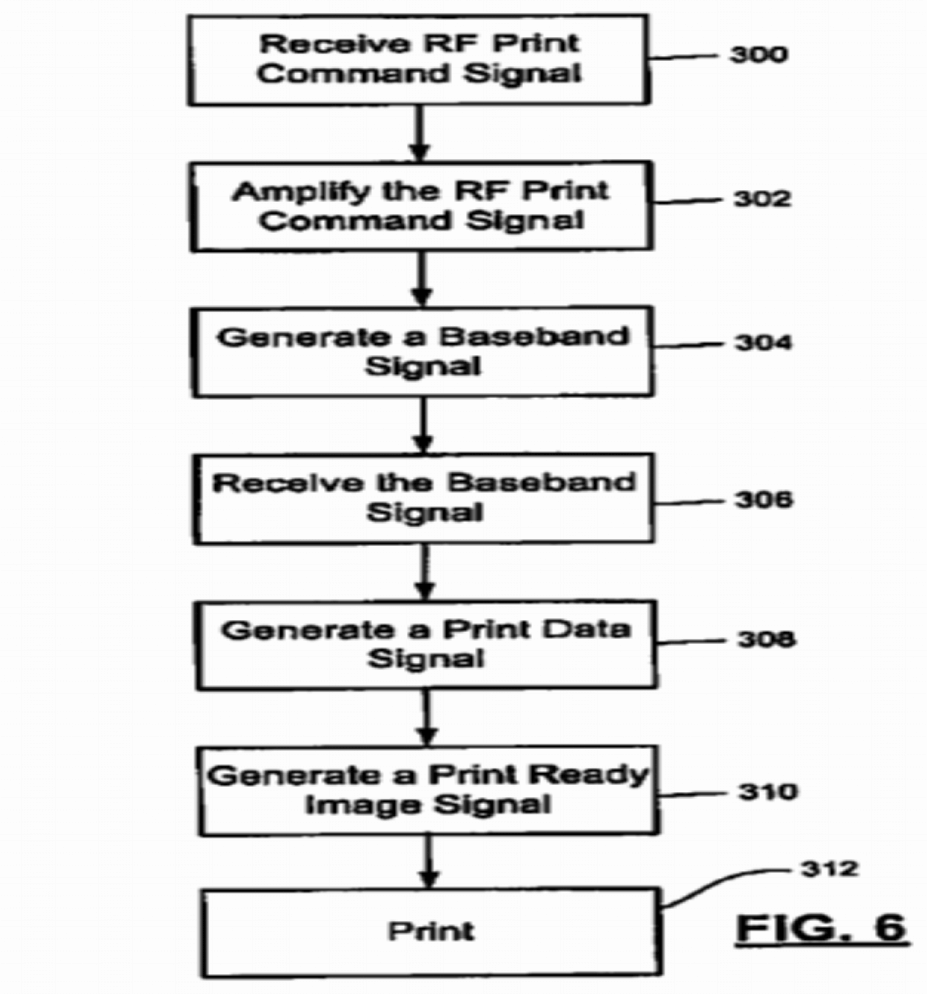

The process in itself is not as intricate as it may seem if we break it down into junctions. The collection of the first RF signal at the receiver generates the second RF signal which then transmits wirelessly to the transmitter. The sequence of these events is what contributes to making the printing process viable.

Circuit Details

Once you establish the theory of operating on the circuit apparatus, you can add additional features to it as well. The handling of the apparatus tends to keep changing mainly due to the fact that PCB’s widely differ in modules. See below for the Specimens of two changing circuit details:

Detail One

The system apparatus is inclusive of a circuit board, a transmitter for printing system, a processing module, and a processor. The manufacturer mounds the first circuit board within the printer. Therefore, configure the first system on a chip so that it mounts on the first circuit board.

The wireless transmitter present on the first chip should perform two functions i.e., (i) wirelessly receive a first radio frequency signal, and (ii) generate a first-baseband signal according to the the first radio frequency signal.

Subsequently, the first processing module present on the second chip is made to (i) process the first baseband signal. And the second baseband signal, and (ii) generate a data signal based on the first baseband signal. The first baseband signal prompts the processor to emit a second baseband signal which in turn implements a printing process.

Detail Two

An application containing an operating system inside a package is delivered. This application is fairly similar to the last one with regard to the generation of a baseband and radio frequency signal. However, the comparison ends there.

This particular method receives the first radio frequency signal from a low noise amplifier. What follows is what usually happens where the first rf signal stimulates the first baseband signal. Based on the second baseband signal, a second radio frequency signal is transmitted from a transmitter to a power amplifier.

The low noise amplifier, the transmitter, receiver, and power amplifier operate collectively as a wireless transceiver. A baseband processing module dispenses a data signal by collectively processing the first and second baseband signal. An imaging module additionally aids in physical printing as a direct result of the previously emitted data signal.

Physical makeup

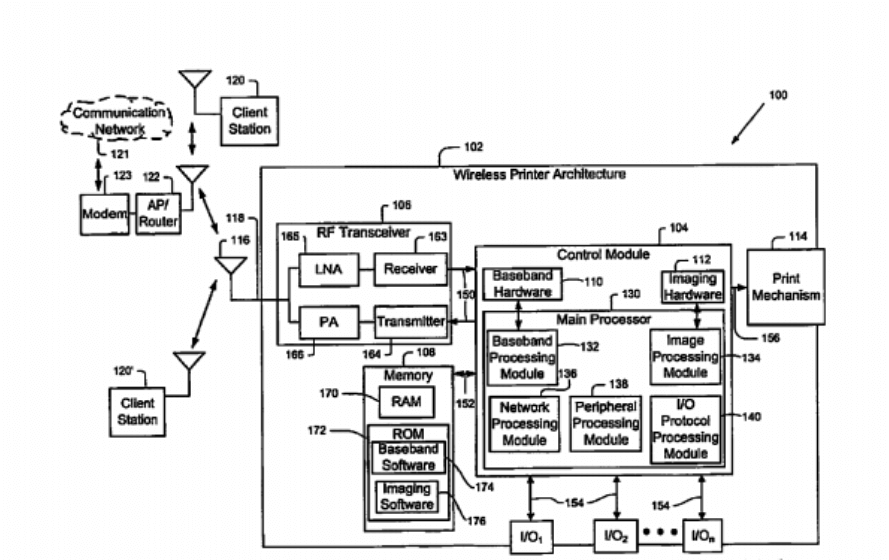

The functional block diagram is the best way to portray the physical layout of the wireless printer architecture. In order to accommodate any desktop printer or shared printer, we make the illustration of a wireless printer communication system.

As shown below the system can compose of a control module, baseband hardware, transceiver, integrated circuit (IC), and a memory. In use, the transceiver which includes both the transmitter for printing and an rf receiver acquires print signals via different locations. However, this depends upon the mode of operation.

The transceiver 106 and the antenna 116 come in action for the reception and transmission of radio frequency (RF) signals to and from the client stations 120". The transceiver 106 includes a receiver 163 and a transmitter 164.

Receiver Operations

During receiver operation, an input of a low noise amplifier (LNA) 165 receives signals from the antenna 116. It then amplifies the signals and outputs them to the receiver 163. During a transmitter for printing operation, the power amplifier (PA) 166 receives an output of the transmitter 164. These outputs amplified signals to the antenna 116.

Although you can't see it thereof the transceiver 106. It is bound to include a processor and other standard elements and components. Such as a frequency synthesizer, a phase-locked loop (PLL), and a voltage-controlled oscillator (VCO).

The transceiver 106 may have mixed-signal components, analog, and digital components. It may have multiple layers that are associated with various protocols for wireless communication.

The top left corner is for the RF transceiver and its physical architecture. That protrudes through a transmitter and receiver vertically attach to the LNA and PA.

Before the advent of PCB, manufacturers were using an exhaustive process for the creation of circuits. These processes often led to avoidable errors. The micro version of a larger circuit has evidently made the lives of many considerably easier.

Transmitter for Printing System: Take Away

A circuit board has almost never been more interesting especially when you pair it with detailed illustrations that conjoin elements of the transmitter for printing and radiofrequency architecture particulars. The circuit board continues to fascinate owing to the magnitude of system chips and baseband signals. This all contributes to making the printing process commercially possible in the least.

For more information regarding our Transmitter products and services, you can contact us today.