Water Pressure Transmitter: How Effective It is Across Industries

How Industries are Benefitting from Water Pressure Transmitter?

Do you know equipment like a water pressure transmitter is helping industries save some big dollars on maintenance costs? An increasing number of sectors are automizing their processes using smart devices like a water pressure transmitter. And allowing machine-to-machine communication and enhancing their efficiency.

Communicating with the controller is the primary task that a water pressure transmitter performs. Based on its primary job, industries use this smart device in various applications.

You May Also Read: Working Principle of Silicon Pressure Transmitter

Below we define what makes a pressure transmitter necessary industrial equipment, what applications it is used in and how industries are benefitting from it.

What is A Water Pressure Transmitter?

A water pressure transmitter records the pressure of water flowing in a system and helps the controller in monitoring and controlling the process. It can also use pressure information and determine the level of water in a stagnant system.

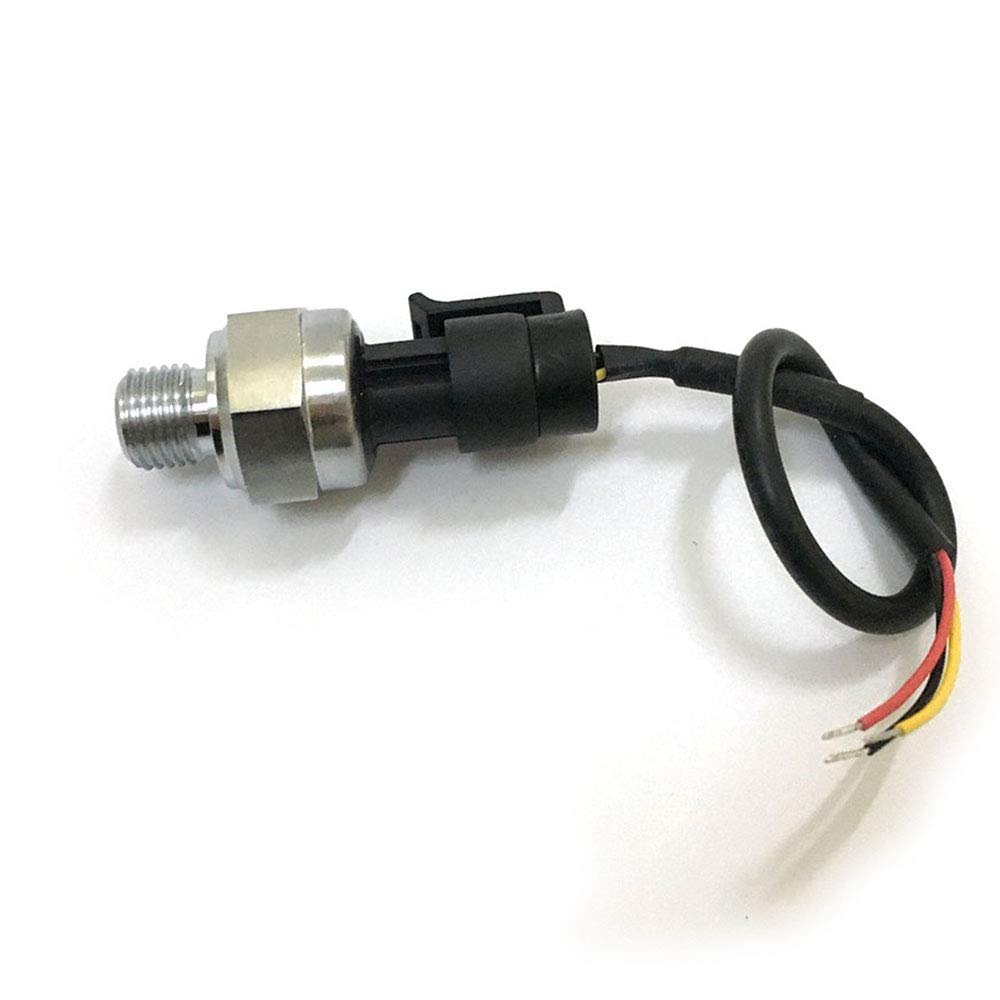

A pressure transmitter consists of a pressure sensor, a signal amplifier, and a transmitter.

The pressure sensor consists of a diaphragm that deflects when the system fluid exerts pressure on it. The transmitter translates this diaphragm constriction into electrical signals. Then it conditions these electrical signals with a signal amplifier and transmit them over to the controller.

After receiving signals from the pressure transmitter, the controller controls the process variable and displays the signs in terms of pressure for humans to see.

Industrial Applications of a Water Pressure Transmitter

A water pressure transmitter is an integral part of the industrial process control system. Moreover, it also records crucial process data and helps the operators take necessary action.

Following are some of the most common applications of an industrial water pressure transmitter.

Monitors Process Flow Rate

Measuring flowrate in any system is vital in controlling the entire process and ensuring that it runs smoothly.

Industrial control systems employ water pressure transmitters to control process flows by monitoring the flow rate of water. A differential pressure transmitter is usually used for this task.

The differential water pressure transmitter uses two sensors located at a different point across the pipe through which the flow is to be measured. Design engineers place an orifice plate inside the line. The orifice restricts the flow of water and thus generates a pressure drop.

The pressure transmitter picks up this pressure drop as the difference in pressure across its to sensors. Since there is an inverse relationship between water flow rate and pressure, using this principle, the transmitter generates an output in terms of flow rate.

In this way, a pressure transmitter helps the control system monitor and control the flow rate of water in any system.

Measures Liquid Level

The ability to measure liquid level is another feather is the water pressure transmitter’s hat. A water pressure transmitter, owing to this feat finds its application in industrial over-flow monitoring systems among other areas.

There are three types of pressure transmitters that most industrial processes use to monitor the level of water.

A submersible water pressure transmitter sits in the bottom of a water tank and measures the pressure of the water above it. The pressure at the bottom of the tank increases with the rising level of water. Thus, as level increases, water pressure transmitter records an increase in pressure and notifies the respective authority (controller or any signal) and plays its part in avoiding an overflow.

The other two types of pressure transmitters used for water level management are gauge pressure transmitters and differential pressure transmitters. Gauge pressure transmitters work in the same way as submersible transmitters.

However, a differential pressure transmitter is used to monitor the level of liquid in a closed vessel. It works by measuring the pressure of air enclosed between the top of the sealed container and the surface of the water inside the vessel.

Measures Pipe Pressure

Water pressure transmitters measure the pressure flowing inside a pipe. They monitor the pressure of water flowing inside a pipe and work in unison with VFD, and VSD pumps to distribute water across all industrial channels uniformly.

When the pressure of the water flowing in a pipe drops, the pressure transmitter senses it and notifies the controller. The controller then communicates with the pump, and the pump increases its power to pressurize the water flowing in the pipe.

Determine Pipe Leaks

Water pressure transmitter also makes a positive contribution to conserving energy by helping industrial technicians quickly locate leaks in water pipes and fix them.

To locate water leaks, pressure transmitters are installed along the length of the pipe. Each pressure transmitter measures the pressure of water flowing in its region.

When there’s a leak, the water pressure in the leaky region drops. Therefore, the pressure transmitter that displays the lowest pressure reading or the largest pressure drop indicates that there’s a possible leak in its local region.

Pump Inlet and Outlet Pressure Measurement

Industries use numerous pumps all across their processes. Monitoring pump inlet and outlet pressure are critical for the safety of the pump, piping and all the downstream equipment.

Water pumping systems use water pressure transmitters at the inlet and outlet of the pumps to measure and hence control the pressure of water entering and exiting the pump.

How Do Industries Benefit From A Water Pressure Transmitter?

Industries are reaping numerous benefits from water pressure transmitters and the automized control systems. In the next few lines, we are discussing some of the most prominent industrial services of an industrial pressure transmitter:

Important Part of IIOT

IIOT stands for Industrial internet of things. IIoT involves machine-to-machine communication and eliminates human interference, thus increasing the efficiency of the entire process.

A pressure transmitter is an essential component of the IIoT. By utilizing smart capabilities of devices like a pressure transmitter, IIot has bestowed many industries with a significant economic boost. It has reduced its repair and breakdown cost and allowing for predictive maintenance.

Allows Effective Process Control

The water pressure transmitter communicates directly with the process controller. In this way, whenever the system pressure deviates from its setpoint, the pressure transmitter detects it and informs the controller. The controller then works to bring the pressure variable back to its set point and eliminates the disturbance.

Thus, a pressure transmitter helps the industries in minimizing the disturbance in their processes.

Measures a Wide Range of Pressure

The pressure variables in industrial processes are scattered over a broad spectrum. A pressure transmitter is a very versatile device when it comes to measuring a wide range of temperatures.

Efficient pressure transmitters can measure pressure as low as 1-inch of H2O. And as high as over 10,000 pounds per square inch.

Works to Protect Industrial Pumps

As we mentioned above, water transmitters are present at the pump inlet and outlet to monitor the pressure of entering and exiting the water.

If the pump exiting pressure is too high, it can damage the downstream equipment and cause the pipe to leak. A pressure transmitter located at the pump outlet monitors the force of water, leaving the pump and stops the pump if the pressure is too high.

If the pressure of the water entering the pump is too low, it can cause the pump to starve. Pressure transmitters located at the pump inlet can help in determining when the pump is starving by indicating lower than normal pressure.

Moreover, starvation can cause cavitation in the pump. Prolonged cavitation can cause severe damage to the pump. A water pressure transmitter placed at the pump inlet, by indicating when the pressure is too low, also helps in preventing pump cavitation.

You May Also Read: Why Use Calibration Software for Pressure Sensor for Sewage Treatment?

Conclusion

An efficient control system is what enables the industry to operate in profit. A control system can do nothing without sensing and transmitting devices like a water pressure transmitter. Instruments like pressure transmitters tell the controller when it has to come into action and also help it determine what action it has to take.

A water pressure transmitter is exceptionally effective across industries as it finds use in many industrial applications, from monitoring liquid level to measuring pump pressures.

Moreover, industries that use pressure transmitters and controllers also benefit from IIOT and manage to protect their pumping equipment from high or low-pressure damage.

For More Information Contact Us Today!