Water Tank Pressure Transmitter: Common Problems

Common Problems in a Water Tank Pressure Transmitter

Water tank pressure transmitter finds numerous applications in processes such as flow-control, overflow monitoring, pressure measurement, and level detection. It works in unison with an ADC or a controller to control the process variables.

Given so many critical applications of a pressure transmitter, it must keep working efficiently. But, like all other devices, a water pressure transmitter is also prone to encountering some problems during its service.

You May Also Read: Water Pressure Transducer: Selecting and Specifying Accelermotors

In this article, we will start by discussing some common applications of a pressure transmitter. Then we will see what factors can contribute to water pressure transmitter malfunction.

What is a Water Tank Pressure Transmitter?

Simply put, a pressure transmitter detects mechanical system variables and converts them into electrical signals. In this way, it helps the computer or other controllers to control the process.

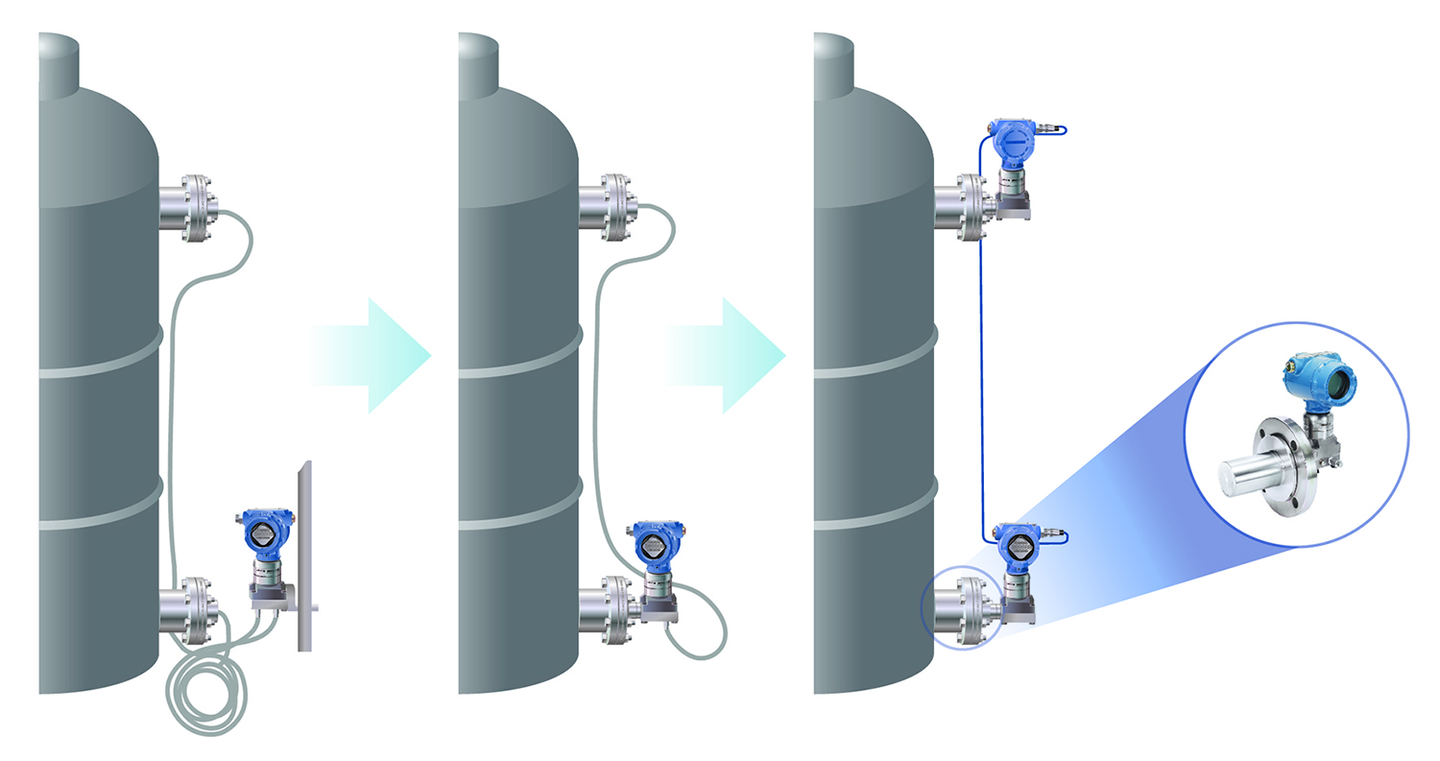

A water tank pressure transmitter consists of a sensing element and a transmitting element. It monitors hydrostatic pressure of the water tank. And may also measure the pressure of flowing water and monitor its flowrate.

The sensing element of the transmitter, which is often referred to as an accelerometer, consists of piezoelectric materials. These piezoelectric materials produce a charge when they encounter mechanical stress.

Thus, when water applies pressure on the seismic mass of the sensor, it induces a charge or a change in capacitance or resistance in the electrical circuit of the sensor. This charge is translated into electrical signals which are transferred to the controller.

So, a water pressure transmitter works in combination with an intelligent controller. And monitors and controls water flow and storage systems.

Applications of a Water Tank Pressure Transmitter

The water pressure transmitter can be used for a wide variety of systems involving water as the system fluid. Some of the most common applications of water tank pressure transmitter are:

Monitor Level of Water

The most obvious and common application of a water tank pressure transmitter is to monitor the level of water in a tank or a vessel.

In such applications, a pressure transmitter usually finds its place at the bottom of the tank. It determines the level of water of the tank by determining its hydrostatic pressure.

In this way, when the level of the water in the tank begins to rise, the pressure transmitter senses an increase in pressure and alerts the controller of a possible overflow.

Measuring Flow Rate of Water

Another potential application of a water tank pressure transmitter could be to monitor the flow rate of water entering and exiting the tank.

A water tank pressure transmitter works in the inlet and outlet line of a water tank. Its accelerometer detects the increase or decrease in the flow velocity. An increased flow of water would exert a greater force on the pressure sensor. And a decreased flow will exert lesser pressure. In this way, the transmitter can relate an increase or decrease in the system pressure with increasing and decreasing flowrate and can help monitor and control process flow rates.

Monitoring Pressure of Water

Monitoring the pressure of water, especially at the pump’s inlet and outlet is important because a decreased pressure at the inlet can cause the pump to cavitate. And an increased pressure at the inlet can cause damage to the downstream equipment.

A water tank pressure transmitter finds its place at the inlet and outlet of the pump and monitors the pressure of water entering and leaving the pump. It prompts the operators or controllers if the pressure drops below and rises beyond the setpoint.

Efficient Pressure Distribution

A water tank pressure transmitter also plays its part in proper distribution of water in high-demand areas such as industries and high-rise living areas.

A pressure transmitter in such applications senses a drop in the line pressure of the water distribution system. It informs the variable frequency drive pump (VFD) of this pressure drop. After knowing that the pressure has dropped, the pump increases its speed to pressurize the water and compensate for the pressure drop so that water reaches all recipients.

Some Common Problems of The Water Tank Pressure Transmitter

No matter how efficient a device is, problems are inevitable. These problems can arise due to systematic errors, random errors or operator errors.

If you nip these problems in the bud when they first arise, you can ensure the long life of your device. And if these problems are left untreated, they could result in more detrimental issues that could lead to devise failure and even accidents.

Inaccurate Water Level Due to Vapor Pressure

As we discussed above, the most common application of a water tank pressure transmitter is to monitor the level of water in the tank by measuring the hydrostatic pressure.

Since water evaporates wherever it is, thus vapours will accumulate in the tank if it is not vented to the atmosphere. These vapours will also exert pressure on the transmitter at the bottom which will lead to inaccurate pressure measurements and thus inaccurate readings of level in the tank because the vapours are not part of the water level but are exerting pressure.

To counter this problem, you can either ensure that the top of the tank is open to atmosphere or use a differential pressure transmitter that can measure the difference between the vapour pressure above the water surface and the pressure at the bottom of the tank.

Inaccuracy Because of Using the Wrong Transmitter for Your Application

Pressure transmitters are application-specific. That means that each application requires a pressure transmitter to have certain specifications. These specifications may include operating pressure range, accuracy, operating temperature range, etc.

Thus, using a pressure transmitter not designed for your system may present problems in terms of accuracy and process control.

To ensure accuracy in the pressure transmitter readings, you must use a pressure transmitter that is right for your application.

Shocks

Water tank pressure transmitter has to bear pressure spikes and shocks more often than not. A pressure transmitter can experience fatigue failure due to continuous low-level shocks.

Once damaged due to shock, the pressure transmitter may present problems such as damaged wires and electronics and decreased durability, which may ultimately lead to distorted output signals.

Damaged Diaphragm of the Transmitter

System overpressure is another very common occurrence for a water tank pressure transmitter. Overpressure occurs when the system pressure exceeds beyond the pressure range of the transmitter.

Normally, transmitters can withstand certain levels of Overpressure. But if the pressure exceeds these levels, it can cause severe damage to the transmitter’s diaphragm.

A pressure transmitter with a damaged diaphragm manifests itself as bad output signals, no signals at all, or failed sensitivity to changes in system pressure.

You can overcome this problem by employing a pressure relief valve or a pressure snubber to minimize system overpressure and protect the transmitter.

Short Circuit in The Transmitter’s Wiring

Water tank pressure transmitter stays in constant contact with water. If the transmitter electronics are not properly sealed, water may seep into it and create a short-circuit in the transmitter’s wiring.

A short-circuited transmitter may fail to measure pressure accurately and can lead to more severe accidents as well.

To prevent this problem, you should employ a pressure transmitter that is sealed from the process media and is made of materials with an IP-65 and relevant NEMA ratings.

Electrical Interference

Electrical interference or noise is a very common problem in pressure transducers, especially those employing voltage output signals.

Noise is a random variation in output voltage which often has low amplitude but is still undesirable.

Electrical noise can defer the accuracy of the pressure transmitter and severely distort the output signals.

Current output signals provide the best protection against electrical noise. Moreover, to further minimize this problem, it is best to isolate your device from surrounding electromagnetic and radiofrequency sources.

You May Also Read: How to Ensure Longterm Stability of Air Compressor Pressure Sensor

Conclusion

Water tank pressure transmitters can develop problems over time. Some of these problems can be minor, and you can mitigate them simply by recalibration. However, some issues can be more serious, which can not be solved by reconfiguration of the device.

The more severe problems are often contributed by factors such as misapplication of the device, short circuit, electrical interference etc.

Getting the right pressure transmitter for your application, then protecting it against system problems such as Overpressure can protect it from developing serious measurement problems and ensure that your transmitter keeps working efficiently for a long.

For More Information Contact Us Today!