Working Principle of Silicon Pressure Transmitter

What is Silicon Pressure Transmitter?

A Silicon pressure transmitter is a kind of pressure sensor that consists of a silicon-based diaphragm. They have the sensing ability which provides extreme flexibility as well as semiconducting properties. This helps the diaphragm in detecting straining gauges that implant in the silicon-based elements which also produces a high level of sensitivity detection. Thus, making it the most acclaimed type of pressure transmitter used in manufacturing procedures.

The Silicon pressure transmitter is the most common transmitter in comparison with other sensors. It has a wide set of use which includes energy preservation companies, automobile industries, artificially intelligent development companies, automated industries, and much more. The following discussion includes its features that relate to its physical, structural, and performance traits.

You May Also Read: Why Use Calibration Software for Pressure Sensor for Sewage Treatment?

Therefore, making it the most popular element that is being used industrially as well as in many other fields. It is multi-functional and stable for a million uses.

How Does the Silicon Pressure Transmitter Work?

Silicon pressure transmitter can detect the pressure levels that induce whenever a procedure conducts. As soon as the pressure detection occurs, the transmitter converts it into using the input specifics for producing the right electric output.

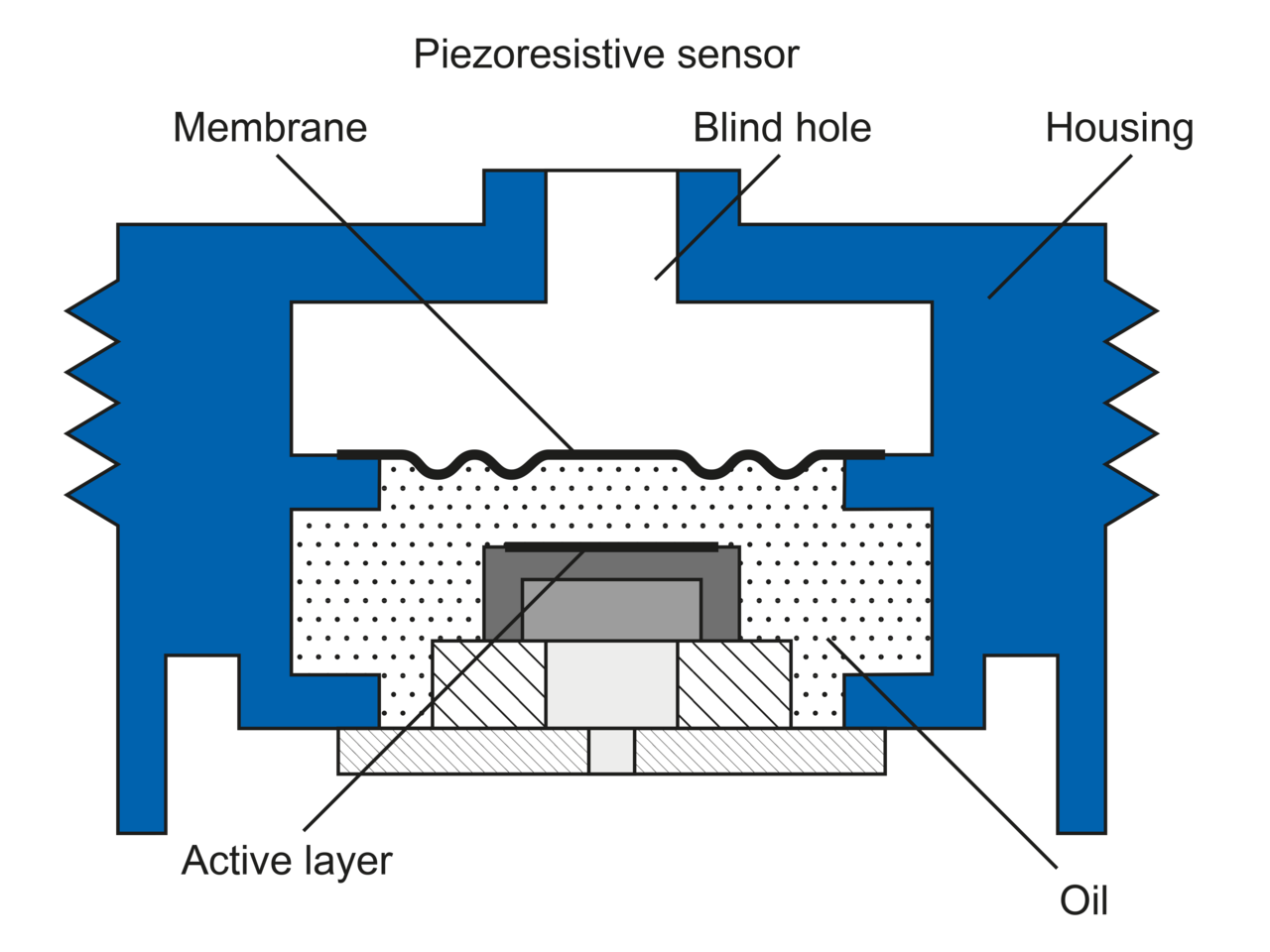

They have major use in almost all industrial and manufacturing applications. You can also say that that a Silicon pressure transmitter works similar to the Piezoresistive Pressure Sensor. The basic working principle behind it is that the external pressure translates to the sensors attached to the diaphragm.

The diaphragm is usually of steel or ceramic. Due to the inserted pressure, the diaphragm creates a slight relocation that comes in proportion to the pressure applied by the intermediate zone. This causes the resistance of the sensor to switch accordingly.

The dispersed Silicon pressure transmitter diffuses the sensors into changing the electrical signals. This way they perform the conversion and produce the desired output according to the input specifics. They have a great production performance with enduring high-pressure levels with disturbing their linearity with precision. Due to their high gauging factor, they are able to endure a high level of disturbance in the matter of pressure and temperature.

Advantages of Silicon Pressure Transmitter

There are various advantages of using a silicon-based pressure transmitter. They have laid a solid foundation for the development of further procedures that require sensing pressure and converting to electrical signals. These kinds of pressure sensors use silicon elements to sense a change. They have much to offer due to their size, nature, and responsive qualities.

A great way to understand the working principle of a silicon-based sensor is to understand its nature and properties. This can help in putting it to better use in the applications that can extract the most benefit out of its qualities.

They are small yet light in weight. Moreover, they are reusable because they stay stable by giving vigorous outputs and respond to the sensitiveness of the pressure applied at different levels.

Elastic in Nature

The diaphragm of a silicon transmitter is elastic in nature because it has a silicon-based structure. Hence it is unbreakable and has remarkable qualities in sensing the changes in the diaphragm when the pressure level changes.

Low Hysteresis

The high level of elastic nature of silicon bonds and integrates with the straining gauges produces a construction. This construction has very low hysteresis. This ensures that pressure levels entering the process are exact. It also helps in leaving the least amount of impact on the direction of pressure. The low impact ensures the output to be precise and according to the input readings.

Gauge Factor is high

Moreover, due to the stretching and squeezing of the gauging factor during the process, the strain is very high. Here, the silicon acts as the semi-conductor and introduces its resistance qualities. This leads to induce an increase in the sensitivity of the diaphragm and it starts detecting the changing pressure more closely. Hence, the change in diaphragm according produces the right amount of electric circuit to perform the given output. This also improves the signal quality as well as easy signal conversion.

Size and Light in Weight

Silicon Pressure transmitters are widely adopted due to their size and structural qualities. The combo of chemical engraving, incapacitating, and disguising techniques bring the production of silicon sensing elements to life. The smaller in size the lesser it will impact the main structure and render the device more useful without occupying much space.

It is always better when dealing with machinery and manufacturing elements, to produce such equipment that adds to the abilities of the design rather than just adding weight to the design. Currently, engineers are working on producing even smaller silicon designs to fit in the sensors without affecting the effectiveness of the production.

Low Obligation to Acceleration

Another added benefit of the small size and light weighted-ness of the silicon transmitter is that they have a very low obligation when it comes to acceleration. Acceleration may be due to the introduced pressure levels. The pressure levels keep on accelerating during the procedures which may cause shocks or vibrations throughout the machinery.

Silicon-based parts are less likely to have an impact on these shocks and vibrations. They are basically shock absorbers. With this high level of endurance to impact they have earned an irreplaceable reputation for being robust with manufacturing procedures.

Stability Factor

Silicon in itself is acclaimed for its robust stable qualities. Since it is a semiconductor, the straining gauges are of silicon. As time passes, straining gauge bonds can depreciate or alter with added constant pressure and temperature levels. This can cause instabilities in the transmitter show. Hence the silicon semiconductor gauges are particularly stable in such situations.

Dynamic Performance Rate

The earlier features show those silicon-based transmitters are much more sensitive to changing pressure levels. Due to this sensitiveness, the performance rate is quite dynamic. The response time is minimal which makes it the most preferred item when installing sensors or transmitters. This dynamic quality makes it more preferable for detecting high and constant pressure level changes.

High-Pressure Control

They have a stiff build that can endure high-pressure levels even at the peak time of the applications. The elasticity of the diaphragm helps in adjusting the pressure levels as such that the performance is at its optimum. Thus, the control remains within the power of the silicon-based elements on how much to adjust to the building pressure.

You May Also Read: Pressure Transmitter for Vitalization System - Ould Sensors

Summary

It is very important to understand the working principle behind a Silicon Pressure Transmitter. To understand it fully there are a few things that need consideration. A complete silicon pressure requirement includes the correct pressure range, overpressure endurance, output signaling, dynamic response quality, and accurate output, right kind of electrical connection, process connection, size, temperature ranges, shock, and vibration endurance.

Once ensured that your silicon pressure transmitter fulfills the above requirements, it is undeniable that the results are sure to put one in wonderment. They have such robust qualities that fit almost all the industrial and manufacturing functions. It has a directly proportional relationship with all kinds of factory-based process. Therefore, it is a leading element in many fields whether it is technical or industrial.

For More Information Contact Us Today!