Instruments Used for the Pressure Sensor for Sewage Treatment

How does Pressure Sensor for Sewage Treatment Works?

The sewage water is the wastewater used by the community. It is black or grey water and has a foul smell. In order to clean the wastewater from contaminants, we perform the sewage treatment using Pressure Sensor for Sewage Treatment.

You May Also Read: What are Air Compressor Pressure Transducer Measurement Issues & Criteria?

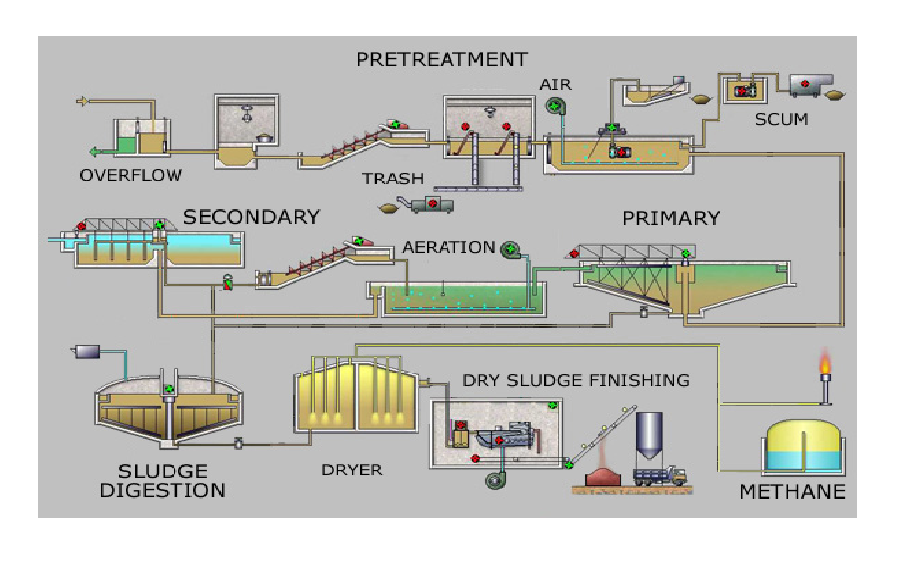

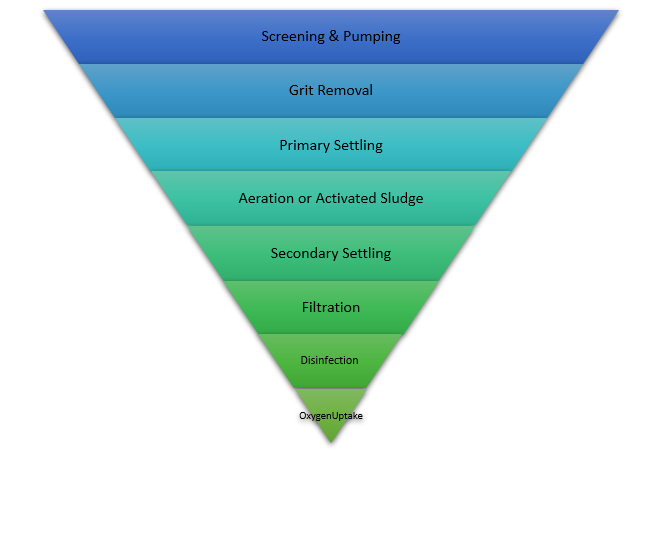

Therefore, to remove these contaminants, different chemical processes take place. The three process steps of Sewage treatment are:

- Primary Treatment (temporary holds the sewage, the settled and floating particles are removed and then released for secondary treatment)

- Secondary Treatment (to remove dissolved and suspended biological matter)

- Tertiary Treatment (final cleansing process)

- Fourth Treatment Stage

Pressure Sensor for Sewage Treatment: Sewage Treatment Steps?

The sewage treatment procedure includes the following step;

Methods to treat sewage:

The four common methods to treat sewage are:

- Physical Water Treatment

- Biological Water Treatment

- Chemical treatment

- Sludge Treatment

Technologies Used to Neutralize Water?

The modern manufacturing process relies partially on water. On the elementary level, water is essential to turn raw material into basic manufacturing resources. Furthermore, water is also required to clean, combine and transform them into daily life products.

During the process, water becomes wastewater due to its exposure to contaminant so it has to go through other rigorous treatment before you release it into natural reservoirs.

Moreover, most of the Industrial factories are now doing on-site treatment of waste water to cut the costs, and to recycle it back to the manufacturing process.

Moreover, the wastewater cleaning process is based on multiple steps. This process cleanses water from harmful bacteria, chemicals, organic and inorganic compounds of water.

Following are the technologies used to neutralize water and to remove impurities from water;

- Reverse Osmosis System

- Ultrafiltration System

- Vacuum Evaporators

- Vacuum Filters

- Paper bed Filters

- Solid Bowl Centrifuges

- Tramp Oil Separators

Types of Instruments Used for Sewage Treatment:

To treat waste-water the Industrial manufacturers used the 4 types of basic instruments;

- Level Instruments

- Flow Instruments

- Water Quality Monitoring Instruments

- Pressure Instruments

Level Instruments:

We use level instruments to maintain liquid and gas levels in pipes, tanks or silos in wastewater treatment systems.

Usually, treatment pipes are difficult to access because they are opaque so the system operators depend on level radar, sensors, and transducers to monitor the level of water.

In addition, switches are normally connected with the alarms, pumps, or controllers to adjust the incoming flow of water and gas.

Flow Instrument:

Flow instruments are used for two main purposes:

- To determine the amount of gas or liquid present in the pipe.

- To check the rate at which the gas or liquid is moving through the vessel.

The flow instruments are installed inside the treatment pipes. They measure the volume and mass of gas or liquid at consistent time intervals.

The flowing instrument might be;

- Variable area meter

- Mechanical flowmeters

- Magnetic flowmeters

- Thermal flowmeters

- And, pressure-based meters.

Pressure Instruments:

Pressure Instruments include;

- Transmitters

- Sensors

- Transducers

- Gauges

It is possible to install the pressure instruments on the inside of the waste treatment pipes, pumps, and reservoirs.

In addition, these pressure instruments help industries to maintain safe pressure levels and also prevent equipment failure.

Water Quality Monitoring Instruments

These instruments are integral for industrial wastewater treatment. Water also needs to pass the national and local cleanliness standards to be released in the sanitary sewers.

To measure the treatment process, you need to install the water quality instruments inline. The type of meter required per phase depends on the testing environment.

The system in question is also a matter of concern in this regard.

Use of Pressure Sensor for sewage treatment:

We use pressure sensors for measuring the pressure of gas or liquid and variables such as the flow of liquid or gas, speed, water level, and elevation.

A pressure sensor is an electronic device. We also use it to detect, regulate, and monitor pressure. In addition, it converts pressure into an analog electrical signal.

Moreover, the pressure sensor converts the perceived data into an electronic signal.

Technologies used by Pressure Sensor for Sewage treatment.

There are 6 major technologies used by pressure sensors for sewage treatment:

- Potentiometric pressure sensors

- Inductive pressure sensors

- Capacitive pressure sensors

- Piezoelectric pressure sensors

- Strain gauge pressure sensors

- Variable Reluctance pressure sensors

Potentiometric Pressure Sensors:

Potentiometric pressure sensors use a bourdon tube, Capsule, or bellows. Thus, they drive a wiper arm and provide relatively course pressure measurement.

Inductive Pressure Sensors:

To diverge the gradation of inductive coupling that occurs between the primary and secondary coils of the transformer, Inductive Pressure sensors use an LVDT (linear variable differential transformer).

Capacitive Pressure Sensors:

A capacitive pressure sensor contains a capacitor that has one rigid plate and one flexible membrane known as electrodes.

They use a diaphragm which is deflected by the applied pressure. This results in a change in the capacitance value, which we calibrate to provide a pressure reading.

Piezoelectric Pressure Sensors:

These sensors rely on the ability of the materials. Also, their purpose is to generate an electrical potential when you subject the material to mechanical stress. We call this process as the piezoelectric effect.

Strain Gauge Pressure Sensors:

This sensor relies on the measurement of the change in resistance. It occurs in a material like silicon. When we subject silicon to mechanical stress we name it as a Piezoresistive effect.

Variable Reluctance Pressure Sensors:

It makes use of a diaphragm that is present in the magnetic circuit. So, when the sensor feels pressure, the diaphragm deflected causes a change in the reluctance of the circuit resulting in the change that can be measured and used as an indicator of the applied pressure.

Types of Pressure Sensor for Sewage Treatment:

Pressure sensors are of four types;

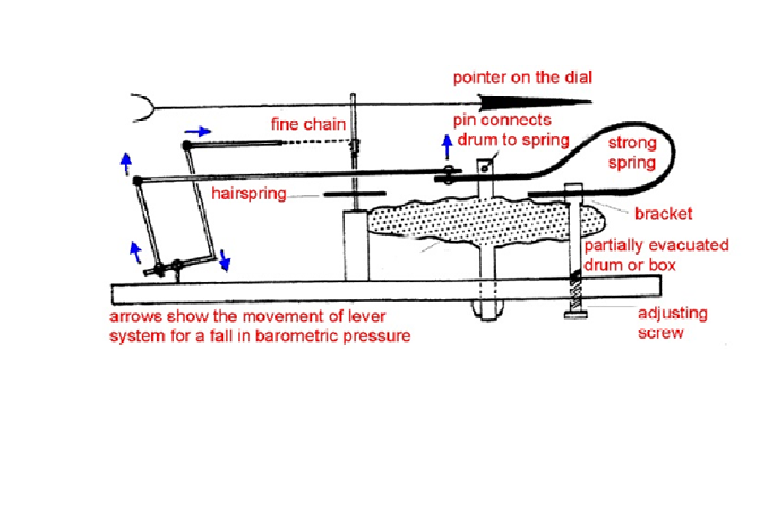

- Aneroid Barometer Sensors

- Manometer Sensors

- Bourdon Tube Pressure Sensors

- Vacuum Pressure Sensors

Aneroid Barometer Sensors:

Manufacturers use a hollow metal casting for the composition of this device. It also has a flexible surface on both the top and bottom.

The atmospheric changes make a change in the shape of this metal casing. Therefore, it is possible to achieve more notable results by the deformation of the mechanical lever’s augmentation.

By manufacturing the sensors in the bellow design, you can enhance the level of deformation.

In addition, these sensors are durable and compact, employing no liquid in their operations.

Manometer Sensors:

It is a fluid pressure sensor. It provides a relatively simple design. The structure and accuracy level of this sensor is greater than the aneroid barometer.

Manometer sensor takes measurements by recording the effects of pressure on a column of liquid.

In addition, the most common type of manometer sensor is in a U-shape. In this sensor, we apply pressure on one side of the tube and co-relates rise at the other end upon displacing liquid and causing a drop in fluid level.

The heights difference between both ends of the tube indicate the level of the pressure.

We also use the scale built into the device to measure the pressure level.

Bourdon Tube Pressure Sensors:

Bourdon Tube pressure sensor is Helical-shaped. The closed end of the tube rotates and indicates the increased pressure.

Moreover, the bourdon gauge contains a tube twisted into the coil or an arc. The coil unwinds with the increased pressure in the tube. At the end of the tube, a pointer is connected to a lever indicating the pressure.

A displacement of 4mm is typical for a 50mm diameter tube.

You May Also Read: Differential Pressure Transducer is Ideal for Monitoring Gas Turbine Air Filters

Vacuum Pressure Sensor:

We also use it to measure vacuum and sub-atmospheric pressures. These pressure rely on the physical properties of gaseous molecules.

Vacuum means the pressure is below atmospheric; we use a conventional pressure sensor to measure vacuum.