What role Pressure transmitter for HVAC plays in HVAC system?

The sensors are important components for the heating, ventilation, and air conditioning (HVAC) systems. Therefore, they are helpful in the maintenance of the internal environment as well as enhancing outdoor efficiency. The pressure transmitter for HVAC is important in the integration of the system to increase its efficiency.

The HVAC systems used the pressure transmitters for the control of the basic operations. These transmitters help to control and maintain the temperature and pressure conditions. Moreover, these systems also use very advanced electrical technologies for technical operations. These advanced technologies and methodologies are important in saving and minimizing energy.

How pressure transmitters are important in an HVAC system?

The pressure transmitters have played an important role in the HVAC systems. Therefore, they monitor the functioning of the different parts of the HVAC system and ensure the enhanced performance. The number of sensors used in the design of the HVAC system is important in the accuracy and reliability of the different components.

The most common type of sensor that we used in the pressure transmitter for HVAC includes the sensors for pressure, temperature, gas samples, and humidity sensors. If we don’t use reliable sensors in these transmitters, the system can face many failures and problems. In most cases, these failures cause poor performance and control of the system.

Why Do HVAC Systems Need Pressure Sensors?

With the increasing applications and demands of maintenance in the buildings, HVAC systems need advanced sensors. However, or the applications of HVAC systems in commercial and industrial buildings, pressure sensors have become the essential part. They are important in the proper control and maintenance of the buildings.

How will you measure differential pressure using pressure transmitters?

The most important factor in industrial and commercial buildings is quality control. Therefore, the purpose of the pressure sensors in the system is to detect the changes in pressure. Any change in the pressure in the rooms and filter is detectable by the sensors. These pressure sensors can alert this change to the technicians.

A pressure transmitter for HVAC is an important component in the HVAC system to detect pressure changes. As the differential pressure is the difference between two pressure values, the pressure transmitter can thus measure this difference. Therefore, the use of a pressure transmitter is important in the HVAC systems for the measurement of differential pressure.

How pressure sensors improve indoor air quality?

The use of sensors in the HVAC system makes the system efficient and effective. However, these do so with the help of the measurement of the flow and pressure of the air within the system. In this way, it ensures the appropriate air distribution within the system. Similarly, the buildings also need the flow and distribution of air through them according to their function.

This is very important in commercial buildings like malls. However, at these places, there is a large number of people and traffic that expel out CO2 into the air. So, for normal and comfortable breathing, it is essential to use the pressure transmitter for HVAC systems. It can tell us how much fresh air is required for normal and comfortable breathing.

How does pressure differential transmitter work?

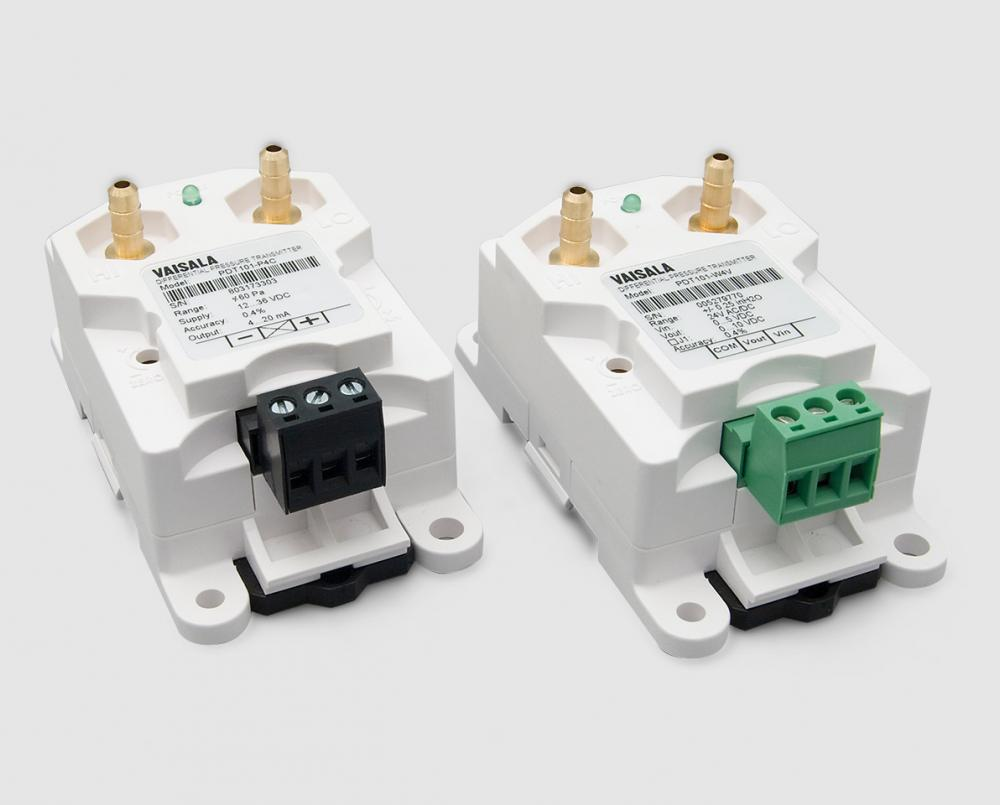

The transmitter that is important in the measuring of the differential pressure has the name as pressure differential transmitter. However, this type of transmitter is important in the measurement of the pressure difference between two ports.

However, there is an output associated with the Pressure transmitter for HVAC. his output of the transmitter depends upon the value of the pressure calibrated for the transmitter. As this transmitter gets the pressure difference, it happens between the two ports. These two ports have the labeling as high and low. In this way, the pressure transmitter finds out the value of differential pressure.

What are the 4 types of pressure?

The pressure is defined as the applied force per unit area of the liquid or a gas sample. The pressure infers us about how much force is applying to the surface area of the fluid. However, the pressure is of different types depending upon the conditions and environment. But it has four basic types. These four types are absolute pressure, differential pressure, atmospheric pressure, and gauge pressure.

What is absolute pressure?

Absolute pressure is a type of pressure that varies according to a reference pressure. We compare it with the reference pressure and state it lower and higher in value. However, the measurement comes quite accurately with the Pressure transmitter for HVAC.

What is differential pressure?

As the name indicates for this pressure, it is a difference between the two values of the pressure. It is a comparison between two pressure values. However, the differential pressure transmitter is useful for its measurement.

What is atmospheric pressure?

The pressure that depends upon the atmospheric conditions is the atmospheric pressure. This type of pressure varies with the change in weather conditions. The pressure that is exerted by the 760mm mercury column at sea level is called standard atmospheric pressure.

What is gauge pressure?

The gauge pressure is a comparison and difference of pressure. In this case, there is a difference between absolute pressure and atmospheric pressure.

What are the types of the transmitter?

The transmitters have four basic types. Therefore, they have different applications in different fields and HVAC systems. Let us go into some detail about these basic types.

What is a flow transmitter?

The flow transmitters are important in the measurement of flow and pressure on the fluid surface. The transmitter uses the sensor system that sends out the signals. Similarly, these signals return from the fluid surface and produce the output. Therefore, the sensor efficiency and reliability are an important factor in the working of flow transmitters.

What are temperature transmitters?

The temperature transmitters are important for the measurement of temperature. However, this transmitter also uses the sensor system for the signaling system. This sensor system produces the signals that return from the surface and form the output signal. It helps in the measurement of temperature. However, there are two further types of temperature transmitters:

Thermocouple type

The type of sensor system in this transmitter is the basis for the name. Therefore, this temperature transmitter uses the thermocouple sensor system for the measurement of temperature. The key to the measurement of the temperature is the use of the electromotive force.

RTD type

The basis for this type of temperature transmitter is also kind of the sensor system. Therefore, this temperature transmitter uses the RTD sensor system. The sensor changes the resistance concerning the temperature. The variance in the temperature becomes the key element to measure the temperature.

What is a pressure transmitter?

This type of transmitter is of prime use in the measurement of pressure. Pressure transmitter for HVAC has three types that are of tremendous use in different applications and processes.

What are level transmitters?

The type of transmitter for the measurement of level properties of the liquid are level transmitters. These level transmitters are also of the seven further types. However, these seven types are point level transmitter, continuous level transmitter, ultrasonic level transmitter, conductive level transmitter, pneumatic level transmitter, capacitance level transmitter, and hydrostatic based level transmitter.